Dr Delana Davies: Knowledge Exchange Hub, IBERS, Aberystwyth University

Dairy cows are high value farm animals requiring careful management to achieve the best results. Since the advent of robotic and high throughput milking, the traditional few minutes available for individual human attention daily has disappeared and new automated technologies have been applied to improve monitoring of dairy cow production, nutrition, fertility, health and welfare.

The challenge for dairy farms in general is to achieve the best possible standards of animal health and welfare, together with high lactation performance and minimal environmental impact. For larger farms, this may need to be done with a much lower ratio of husbandry staff to animals. Recent engineering advances and the decreasing cost of electronic technologies has allowed the development of ‘sensing solutions’ that automatically collect data, such as physiological parameters, production measures and behavioural traits. Such data can potentially help the decision making process, enabling early detection of health or wellbeing problems in individual animals and hence the application of appropriate corrective husbandry practices.

Emerging technology

New technology is focussing on emerging developments in:

- welfare biomarkers (e.g. stress and metabolic diseases),

- activity-based welfare assessment (e.g. oestrus and lameness detection)

- sensors of temperature and pH (e.g. calving alert and rumen function)

The term ‘engineering’ encompasses mechanical, electronic and computer engineering. A key aspect for the implementation of the new engineering technologies in the dairy industry, many of them related to TIC (technologies of information and communication), has been the dramatic reduction in size and price of electronic microprocessors combined with a considerable increase in operating capacity. This has allowed major advances in digital electronics, enhanced data acquisition and storage, faster processing speeds, higher definition video cameras and very sensitive and cheap sensors, amongst others.

The availability of low cost tri-axial accelerometers and wireless telemetry has allowed accurate models of behaviour to be developed and sometimes combined with rumination activity detected by acoustic sensors to detect oestrus; other measures (milk and skin temperature, electronic noses, milk yield) have largely been abandoned. In-line biosensors have been developed to detect markers for ovulation, pregnancy, lactose, mastitis and metabolic changes. Wireless telemetry has been applied to develop boluses for monitoring rumen pH and temperature to detect metabolic disorders. Udder health requires a multi-sensing approach due to the varying inflammatory responses collectively described as mastitis. Lameness can be detected by walk over weigh cells, but also by various types of video image analysis and speed measurement. Prediction and detection of calving time is an area of active research mostly focused on behavioural change.

Identification

The first radiofrequency (RF) identification (ID) system of cattle used a glass encapsulated rumen bolus powered by a battery which was administered orally. RFID is heavily used in the dairy sector, and facilitated by the fact that each lactating animal will regularly come to one specific point to be milked,

regular data downloading allows for individualistic management. Current RFID of dairy cows is still based on large high frequency transponders (i.e. neck collars) although miniaturised low-frequency devices of different ISO technologies are cheaper and readily available (ear tags, injectable devices or rumen boluses).

Wearable devices

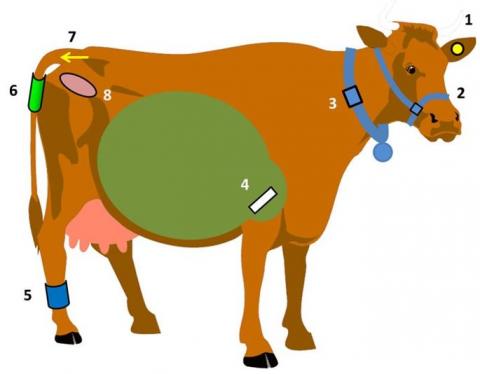

Activity sensors (Fig. 1) in the form of wearable devices are now used very commonly in dairy herds. Most commercially available reproductive management technologies (e.g. oestrous mating, calving) listed in Table 1 are based on activity recording of one sort or another using tri-axial accelerometers (‘SensOor’, ‘Cow Alert’, ‘CowScout’, ‘Qwes’, ‘Activity meter’, ‘Silent Herdsman’, ‘Gyuho SaaS’, ‘HeatWath II’, ‘Heatime’, and ‘HeatSeeker’). They are offered to wear as an ear tag, nose halter, neck collar or leg (preferably rear) pedometer. Some accelerometers also offer information on feeding behaviour (e.g. eating, ruminating, drinking). A special case is the ‘MooMonitor’ which uses pressure sensors for detecting the standing behaviour of dairy cows during oestrous. Simpler devices for heat and mating activity detection use RFID transceivers attached to a harness for bulls or androgenised cows (‘Celotor’). Cows are identified with an injectable transponder in the tail head which is read by the transceiver at mounting.

Fig. 1. Location of engineered devices for in situ data collection in a cow: (1) ear tag, (2) halter, (3) neck collar with counterweight, (4) reticulorumen bolus (in reticulum), (5) rear leg pedometer, (6) upper tail ring, (7) tail head inject, and (8) vaginal bolus. (Caja et al, 2016)

Calving detection may be monitored by measuring tail movement patterns triggered by labour contractions, with devices attached to the tail head containing accelerometers (‘Moocall’) or by the dramatic change of temperature of a vaginal device using thermistors when it is expelled during labour (‘Vel’Phone’ and ‘iVET’).

Reticulo-rumen boluses (‘eCow’, ‘WellCow’, ‘smaXtec pH’) assess rumen function by specific sensors (e.g. temperature, pH, pressure) which might be related to rumen pH for SARA (subacute rumen acidosis) detection and with feeding and drinking behaviour.

Additionally, data provided by an integrated tri-axial accelerometer offers information on reproductive activity, feeding and locomotion for integrated farm management decisions, including lameness detection (‘smaXtec Sensor’). A simpler case is the ‘San’Phone’ only equipped with thermistors informing about rumen temperature and drinking bouts.

For fertility monitoring, oestrus detection collar systems have become widely adopted and are replacing pedometers but do not offer the added capabilities of the new technology of on-line progesterone analysis to detect infertility and pregnancy as well as ovulation. Metabolic disorder monitoring has been enhanced by the development of rumen wireless telemetry to detect subacute acidosis, automated weighing and more promisingly Body Condition Scoring by image capture. Mastitis detection has been developed such that a low cost screening by conductivity and behavioural analysis can be enhanced by automated SCC to validate diagnosis. Lameness detection has advanced with products on the market but mobility scoring has not yet been routinely achieved.

Communication

All of these technologies are capable of identifying livestock requiring attention or ‘at risk’ and communicating with dairy farm staff at any time using M2M communication by App and SMS telephone messages. While mention has been made of several technologies that are commercially available there are many others at various stages of experimental development. It would not be appropriate to comment on the usefulness or otherwise of the individual commercial technologies, since the claims made for accuracy, precision, false positives and negatives are in most cases those of the manufacturer and have not been tested independently. The following observations should however be noted:

- Although manufacturers often claim to offer ‘complete solutions’, no one system individually offers everything that could be achieved by using a full combination of all systems operating together

- Almost without exception, the different technologies operate ‘standalone’, and will not communicate with each other

Technology developments are following two diverse strands, one is to load more sensors onto the animal, particularly onto collars. This means that the sensors can be monitoring the animal continuously wherever she is. The other approach which is inherently cheaper, particularly for large herds, is to have a single monitoring position close or at the milking system through which all cows must pass. The robotic milking machine with its high number of individual cow contacts daily is an ideal place to conduct such individual cow monitoring.

The future

The objective is to assist good husbandry, not replace it, and the deliverable must be as simple as possible.

Who will deliver this assistance, and to whom?

It is evident that there is no shortage of potentially useful technologies, but what is lacking is the skilled herdsman who reduces the information to a simple answer for themselves or their boss (one can be reasonably sure that it will often be a ‘boss’, i.e. the manager of a large unit of some sort). Most probably in future business models the technology will be ‘owned’ by service providers who will be contracted to place it on farm, receive data from it, interrogate, integrate and analyse that data and then respond with the traffic light message, or simply an automatic move of shedding gates from one position to another.

Who will be the customers?

‘Big farms’ is far too simplistic an answer, for some of the big farms of the future might slowly become big by accident rather than specific design, whereas others might be planned big from the bottom up. The wellbeing monitoring system might have rather different requirements, almost ‘rescue’ based in the first instance but cost-benefit proven in the second. The third and arguably most important ‘big farm’ would not be a single farm at all, but a cluster of smaller farms that gather together to dilute investment and overhead costs and then share data in order to maximise the impact of the technology. There are other players too:

- The immediate response will necessarily involve veterinary professionals, either employed or contracted by the farm or the service provider

- Medium term responses will involve dairy consultants, feed advisers and breeding companies

- In the longer term the service provider will share data with national breeding programmes to maximise genetic progress towards improved wellbeing traits.

The combination and integration of these technologies into ‘smart’ husbandry support systems will ensure optimum wellbeing for dairy animals and thereby maximise farm profitability. Use of novel sensors combined with new technologies for information handling and communication are expected to produce rapid and dramatic changes in traditional dairy farming systems.

Table 1: Currently available engineered devices for monitoring oestrus, calving behaviour and rumen function

Oestrus activity behaviour Device location

CowManager, SensOor, Agis Automatisering (Harmelen, NL) Ear

Cow Alert, IceRobotics (Edinburgh, Scotland, UK) Leg

CowScout, GEA (Düsseldorf, DE) Neck or leg

Qwes (Lely, NL) Neck

Activity meter, DeLaval (Tumba, SW) Neck

Silent Herdsman Afimilk (Kibbutz Afikim, IL) Neck or leg

MooMonitor, DairyMaster (Tralee, IE) Neck

HeatPhone, Medria (Chateaubourg, FR) Neck

Gyuho SaaS Fujitsu (Fukuoka, JP) Leg

HeatWath II, CowChips (Manalapan, NJ, US) Tail head

Heatime, EFS (Westmeath, IE) Neck

HeatSeeker, BouMatic (Madison, WI, USA) Leg

SmaXtec Sensor, SmaXtec Animal Care (Graz, AT) Rumen bolus

Celotor (Cali, CO) Harness reader and tail inject

Calving behaviour

Vel’Phone, Medria (Châteaubourg, FR) Vaginal temperature

iVET birth-monitoring (Papenburg, DE) Vaginal temperature

Moocall (Dublin, IE) Tail ring

Rumen function (all rumen bolus applications)

eCow Devon (Exeter, UK)

San’Phone, Medria (Chateaubourg, FR)

Well Cow (Roslin, Midlothian, UK)

SmaXtec pH & Temp Sensor, SmaXtec Animal Care (Graz, AT)

References

Caja C, Castro-Costa A & Knight CH 2016 Engineering to support well-being of dairy animals Journal of Dairy Research 83 136-147