Penyparc Final Report – Labour efficiency and technology ROI

Prepared by Conor Hogan, Dairy Programme Manager, Teagasc Moorepark, Ireland

Key Results

- The current strong position in terms of farm layout and facilities reduces the need for urgent investment. Technologies should be viewed in light of long-term goals

- Calf feeders look like a good potential option in Penyparc’s context — helping manage workload during the peak period, It offered a return on investment of 14% with a pay back period of 7 years

- Cow collar investment offered a 7% return on investment and a total of 14 year pay back on the business/herd’s current technical performance

Background

- Focus on improving farm performance, labour efficiency, and work-life balance through cost-effective technologies

- Existing facilities were modern, efficient, and well laid out offering a good baseline

Purpose of the work

- Evaluate estimated return on investment (ROI) of automatic heat detection and automatic calf feeders

- Identify other opportunities to improve farm performance and work-life balance

Outcomes

- Technology ROI evaluation - Automatic heat detection

Table 1. Investment cost of cow collars

Performance considerations (based on 2024 figures and better expected figures in 2025)

- 6-week calving rate: 81% (already high)

- Empty rate: 13%

- Current performance suggests limited fertility improvement could be achieved through investing in collars

- Health monitoring benefit: limited data to-date to suggest its benefits – could not include in an ROI analysis

- Labour saving:

- Potential to reduce milking to one person during breeding

- Would ease the burden on Rhodri/Sion during breeding (e.g. there doesn’t need to be someone checking cows all of the time)

- There is a need to be conservative in terms of actual labour saving – will be limited to breeding period

Table 2. Cow collars estimate savings

Table 3. Estimate return on investment of cow collars

Comment: Long payback period, limited added value due to strong baseline fertility. ROI is very modest, though intangible benefits (e.g. peace of mind, workload flexibility) may be relevant.

- Technology ROI evaluation - Automatic calf feeder

Table 4. Investment cost of automatic calf feeders

Performance considerations

- Calf rearing area well laid out — feeder integration should be straightforward

- Two stations estimate based on need to keep at least 45 heifer calves per annum

- Will have no significant impact on calf performance or health

- Labour saving:

- Shown to add flexibility (e.g., calves don’t need to be fed straight after morning or evening milking)

- Calves may need to be kept inside and on milk for longer – can lengthen the calf rearing period

- Positive effects in terms of time saving. Table below shows their impact for February, March and April on a sample of Irish farms that implemented the technology (conservatism needed as some of these farms will have had extreme changes in calf facilities)

Table 5. % of labour difference between farms that implemented auto calf feeders vs not on Teagasc Irish project farms

- Assuming 20% labour efficiency improvement – this is with caution as Penyparc’s current facilities should allow for relatively efficient calf management

- Estimated calf care labour input for a 185-cow farm @ 367 hours (based on Irish data). Estimated table below of possible savings. Note: based on estimated data from farms of similar herd size/ facilities and not actual data from Penyparc

Table 6. Potential labour saving with auto calf feeders

Table 7. Estimate financial savings for automatic calf feeders

Table 8. Estimate return on investment of automatic calf feeders

Comment: Better payback period. Lower initial investment is a big help – which can be variable depending on service providers available. Labour savings are clearer and also improves flexibility during calving. Caution is required in terms of already having good facilities and that calves will likely need to be kept in for longer.

How to apply on your farm

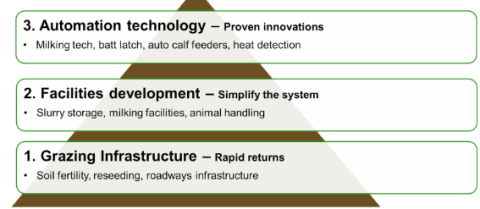

Farm investment priorities should be considered with the matrix outlined in figure 1.

Figure 1. Farm investment priorities

To maximise returns, it is important that investments are made in a planned sequence, prioritising areas that deliver the greatest benefit first. Based on research, the following investment sequence is recommended:

- Grazing infrastructure – improvements in soil fertility, reseeding, and roadway infrastructure are relatively inexpensive and deliver rapid and substantial economic returns.

- Facilities development – as milking accounts for the greatest proportion of work time on dairy farms (circa 33%), milking facilities should be prioritised to reduce milking time. Improved animal handling and slurry storage facilities can also make farms safer and more efficient.

- Automation technologies – innovations such as automatic calf feeders, drafting gates, automatic cluster removers, auto-wash, gap release and automated heat detection technologies can further reduce routine workload. Some automation technologies may not significantly reduce overall labour time but can provide greater flexibility and simplify routine tasks.

Different farms will be at different stages of development, and some investments will deliver greater returns or prove more beneficial depending on the needs of the farmer.

If you would like a copy of the full report, please contact: timtechnegolcff@mentera.cymru