4 October 2018

Dr Stephen Chapman: IBERS, Aberystwyth University.

Take home messages:

- Agricultural pollution is a growing cause of concern

- Membrane technologies can filter nitrogen and other pollutants from agricultural waste streams

- Membrane technologies can also be used to remove and recycle water from slurry

Agricultural pollution is a growing concern, that refers to the contamination of the environment as a result of using products rich in nitrogen, carbon and phosphorus. Pollution can occur when artificial fertilisers, manures and slurry is spread without realising what the crop demands are or what the soil conditions can support. Nitrogen, in the form of nitrate and ammonia, that leaches into a water course from the land can result in algal blooms and oxygen depletion which has devasting environmental consequences. In addition, the cost of treating nitrogen contaminated water to meet drinking water standards is rising and currently costs the UK £120 million.

Environmental concerns over nitrogen pollution has placed a greater emphasis on pollution prevention at source, with the biggest legally binding directive being the Nitrate Pollution Prevention Regulation (2015). In this directive, an area that is designated as being at risk from agricultural nitrate pollution is classified as a Nitrate Vulnerable Zone (NVZ). Wales, along with the rest of the UK is bound by this directive which aims to reduce nitrate leaching into ground water reserves. To avoid a breach of the directive (enforced by fines), any fertiliser or nutrient input within an NVZ must be stringently regulated to ensure nutrient pollution does not exceed the limits as specified in the directive. It is therefore essential that farm businesses within an NVZ must take the necessary management approaches to avoid nitrate leaching

from point sources. Membrane technology provides one proven solution to filter and capture nitrogen from contaminated waste streams and, as such, is an effective management approach which offers the potential to remove water from slurry and to treat the water, so it is safe for discharge or reuse.

The use of membrane filtration systems to treat slurry waste during processing offers many other advantages in addition to pollutant containment. By passing slurry through a series of membranes, with each membrane containing smaller sized pores than the last, target particles contained in the waste stream will be retained, effectively only allowing purified water to pass through. The recycled water can then be reused on farm. Furthermore, because the water element of slurry has been removed, the final weight and volume of the slurry is vastly reduced, improving storage potential and potentially making transport cheaper. Membranes can filter large volumes of water per hour, are compact and take up less space than conventional treatment schemes, and are very simple to operate.

Membranes have been used for decades; however, with an advanced understanding of science, a wide range of membranes have now been developed to specifically treat agricultural wastewater. Different waste streams will have different characteristics; for example, dairy slurry will contain different constituents from swine slurry, e.g. suspended solids such as remains of feed and different nutrients. It is for this reason that use of a potential membrane must be specific for each waste stream. The two main factors that determine the effectiveness of a membrane filtration process are selectivity and productivity. Selectivity, simply refers to the selective nature of the membrane; i.e. what is allowed to pass through, and what is retained by the membrane, which is determined by the membrane pore size. Productivity (alternatively called mass flux) is defined as the volume of water flowing through the membrane per unit area in a given time. The waste stream is then pumped towards the membrane at pressure. Anything in the feed that is bigger than the pore size will be retained against the membrane. A backwashing step, or chemical clean is then needed to remove the captured material from the membrane filters.

There are four main types of membrane filter systems used to separate constituents of varying sizes. The degree of selectivity of a membrane depends on the membrane pore size, and these can be classified as microfiltration, ultrafiltration, nanofiltration and reverse osmosis. Microfiltration removes particles larger than 0.1 µm and operates at pressure ranges between 1 and 15 PSI (0.01 - 1 bar). As such, microfiltration is best suited for filtration of macromolecules such as suspended solids or bacteria. Ultrafiltration removes particles between the sizes of 0.1 and 0.01 µm, using higher pressures of 10 and 100 PSI (0.7 - 7 bar). Ultrafiltration can be used to filter high molecular weight compounds dissolved in a waste stream, such as proteins and carbohydrates in addition to virus and endotoxin removal. Going smaller still, nanofiltration involves membranes with pore sizes of 1 – 5 nm, so anything bigger than 5 nm (0.005 µm) is retained, such as dissolved phosphate, heavy metals and dissolved organic carbon. Nanofiltration typically occurs at pressures between 100 and 435 PSI (7 - 30 bar). Operating at high pressures of 290 – 1500 PSI (20 to 100 bar), reverse osmosis is able to selectivity filter the smallest of constituents such as monovalent ions, such as nitrate, in effect, only letting purified water through a non-porous membrane.

Case studies: Applications of membranes to treat digestate

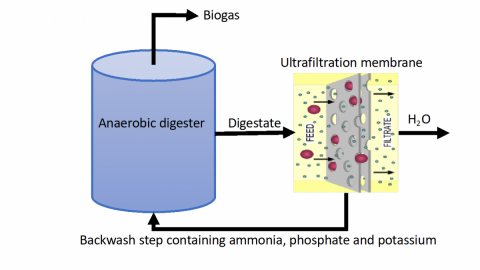

The application of membrane technology for treatment of digestate streams is well documented. In one example, a tubular ultrafiltration (UF) membrane was attached to the back of an anaerobic tank that was fed with pig slurry. The membrane had a total surface area of 1.7 m2 and contained pore sizes of 40kDa. Following anaerobic digestion, the UF membrane was able to remove ammonia, phosphates and potassium from the digestate. Furthermore, the resulting demineralised water was potable and can be applied on-site, increasing on-farm water use efficiency.

Another example that highlights the benefits of using filtration technology to treat digestate waste has also been demonstrated. Here, ultrafiltration membranes coupled to reverse osmosis membranes to treat anaerobically digested swine manure resulted in a 45% reduction of nitrogen and 51% reduction in the volume of digested pig slurry. All these studies show the capabilities of membranes to filter pollutants from organic waste streams whilst simultaneously producing potable purified water that can reused on site.

The application of membrane filtration to treat slurry waste streams is also well documented. In one case, the application of membrane technology was used to recover water from pig slurry using an integrated system of ultrafiltration and reverse osmosis. The cleansed water was recycled and reused on-site

whereas the substances retained by the membrane, such as dissolved organic carbon, nitrogen, phosphorous, and NH4, can be backwashed into sealable containers and either returned to land or used as a feedstock for anaerobic digestion for further biogas production. A more recent study compared the use of two different integrated membrane systems. The first system was composed of microfiltration with nanofiltration membranes and the second system consisted of microfiltration coupled to a reverse osmosis membrane. These integrated membrane units were used to treat dairy wastewater to remove nitrogen and dissolved carbon. In the first scenario, the MF and NF membranes were able to recover 58% of nitrogen which reduced the overall chemical oxygen demand of the resulting stream by 51%. The second system, consisting of microfiltration and reverse osmosis, was able to remove 94% of nitrogen and 84% total organic carbon from dairy wastewater, and therefore presented the greatest applicability in treating dairy waste. Ultrafiltration coupled to reverse osmosis offers the greater application to concentrate mineral solutes from slurry, that can be directly used as fertiliser. The filtrate of reverse osmosis, can be reused as process water or can be further ‘polished’ by nitrogen stripping technology to produce clean water that is safe to be discharged into the watercourse.

Summary

Membrane technology provides effective waste management solutions to the livestock sector operating within a nitrate vulnerable zone. Membranes can selectively filter nitrates and other contaminants from digestate waste streams and from slurry. Ultrafiltration coupled to reverse osmosis offers the optimum approach to concentrate mineral solutes from slurry. At the same time, the filtered water can be reused onsite, effectively increasing the water use efficiency, or safety of water discharged. Because filtration removes the water element from the waste stream, the total volume of the waste stream can be reduced by up to 70% of its original volume, making storage and transport cheaper.