Assessing the effects of LED lighting on productivity and health and welfare in a poultry layers unit

Key results

- Flock egg production increased by 6.1%, worth £27,192 following LED light installation

- Installing LED lights led to an energy cost reduction of £2,724.08 over the next 78 week laying cycle

- A total annual carbon saving of 1,218 kg CO₂e has resulted

Background

The main drivers at Glanalders are to become more self-sufficient in energy while improving bird health and welfare. While there are 20kW solar panels installed on the 16,000 layer bird flat deck system, the energy generated was only contributing around a third of the annual requirement for the shed.

Compared to fluorescent lights, LED (light emitting diode) lights offer superior energy efficiency, a longer lifespan, and critically for welfare, they are generally flicker-free. The ability to customise the light spectrum is another significant advantage of LEDs over older lighting technologies, which often have fixed and less optimal spectral outputs for poultry.

Poultry have greater sensitivity to colours and vision on the ultraviolet spectrum. The presence of different colours, intensity and periods of light can all have an influence on their behaviour and performance. LED lighting has a better spread than conventional lighting, eliminating dark spots and reducing stress. LED’s therefore have the potential to improve stimulation of the birds’ natural day/night behaviour and improve performance

Project aims

- Assess any improvements in energy self sufficiency of replacing the current 2ft light strips with LED lights

- Assess any impact that LED lighting has on health and welfare and productivity of the flock

- Calculate the economic benefit of the new lights

What has been done

Following the departure of the previous flock of hens in March 2024, the new lighting system was installed, with the new flock arriving at 16 weeks of age at the end of April 2024. The new flock was laying from May 2024 onwards.

During the changeover period, the current 54 x 2ft strip lights in the shed were removed and replaced with LED lights. These were supplied by Dalton Engineering Ltd.

Three lines of LED lights were installed, each line with 35 lights. They were 48V/9.6W warm white LED lights.

The project used data gathered and recorded monthly via ‘Eggbase’ software from the new flock of hens compared with the previous flock.

Figure 1: New crop of birds with LED light installation

Outcomes

Bird productivity

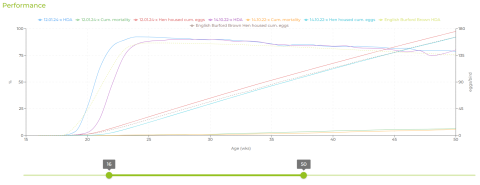

Data from the ‘Eggbase’ software programme was compared for the 16-to-50-week periods of the previous hen crop against the May 2024 flock (Figure 2). The flock introduced after the LED light installation came into lay earlier (blue line), and consequently produced cumulatively more eggs (red line) compared to the previous flock.

Figure 2: Actual and cumulative egg production data for two flocks

Table 1: Egg production numbers for the two flocks

While this manifests as a significant increase in egg production worth £27,192 for the flock introduced after LED light installation (Table 1), there are a number of factors that can influence egg production such as optimising rearing success, ambient temperature, season and day length, although length of day for the flock is controlled by a prescribed lighting plan in the early stages to bring them into lay.

There were no discernible differences in health, appearance or mortality rate between the two bird crops.

Energy efficiency

In making energy saving calculations for the LED light installation, the following assumptions have been made:

- Laying cycle of 78 weeks

- Lighting cycle during laying cycle:

- 10 hours per day during initial 8 weeks of laying cycle

- 14.5 hours per day during remainder of laying cycle

- Project capital spend - £9,200

- Cost of grid electricity - 30.85 p/kWh

- Grid emissions factor - 0.20705 kg CO₂e/kWh

Table 2: Energy consumption comparison

The figures shown in Table 2 lead to the following electricity and carbon savings:

Total electricity saving over 78-week period = 8,830 kWh

Total carbon savings over 78-week period = 1,828 kg CO₂e

Total electricity savings annually = 5,886 kWh

Total carbon savings annually = 1,218 kg CO₂e

Table 3: Financial analysis of energy savings

* Note: No account has been made for replacement frequencies of luminaries in these calculations. LED lights should typically last up to 5 times longer than a fluorescent tube which would reduce the payback period.

Conclusions

The installation of the LED lights has proved a worthwhile investment with the energy savings alone covering the capital investment in 5 years. The increase in egg production of 6.1% from the hens coming into lay earlier has been dramatic and amply covers the installation cost, although many factors can influence the success of a new flock coming into lay. There were no notable differences in health and welfare outcomes for this flock compared to the previous flock.

Carbon savings of 1,218 kg CO₂e annually have also been made by replacing the old strip lights with the more energy efficient LED lights.