10 September 2019

“Multicut” is a term that has become widely used to describe a silage system which starts with an earlier first cut, followed by more frequent cuts throughout the summer.

Why multicut?

The system allows the farm to grow more forage of better quality. It requires a change of mind set, looking at the clamp in terms of total megajoules (MJ) of energy and kilogrammes (kg) of protein as opposed to just tonnage. You will not get “barn busting” yields at any cut, but over the course of the season you will conserve more dry matter/hectare (DM/Ha) as the grass aftermaths are greener and the field will photosynthesise for more days of the year.

Higher quality silage contains lower fibre levels and this allows increased forage inclusion rates in diets. With this system all cuts should be of similar quality and quantity as grass is cut at shorter intervals. The system uses the same principles as rotational grazing in terms of allowing grass time to recover between defoliations whilst utilising as much growth as possible before leaves die back.

Promoting more growth per hectare improves land utilisation allowing higher stocking rates. This in turn reduces the necessity to source forage from elsewhere giving greater control over sward quality.

The system reduces risk in three ways.

- higher forage: concentrate ratios reduce the risk of rumen upsets

- more milk from forage reduces the farm’s exposure to volatile feed markets

- smaller cuts can be made more quickly meaning shorter weather windows can be taken advantage of. If rain does hit, smaller volumes can be dried more quickly and each individual cut makes up less of the total feed requirement

Preferred grass mixes:

Grass mixes should use varieties from the Recommended Grass and Clover List as these are proven for their yield, quality and disease resistance characteristics and suitable for the farm’s specific conditions. Intermediate and late perennial ryegrasses will provide a quality product throughout the season.

Italian ryegrasses tend to be more difficult to manage, they are harder to get dry at first cut and mid-season quality is much lower than the perennials as they run to seed more quickly.

A regular reseeding policy will maximise quantity and quality. Grass breeding moves on significantly each year and advances should be taken advantage of (you would not generally use a straw from a bull that was 20 years old and expect the best results). Even under excellent management, swards will deteriorate over time. Ideally perennial swards should be reseeded or rejuvenated every 5-6 years so aim to reseed 15-20% of the area each year so you don’t end up with all swards needing attention at the same time.

Fertiliser:

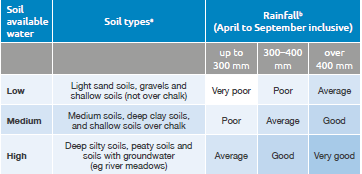

If we are expecting grasses to produce more then we need to ensure that they are given every opportunity to achieve those targets, an elite athlete does not perform on a sub-standard diet. How much to expect will depend on the grass growth class of the field and farm and this is predominantly determined by soil type and rainfall, but aspect and altitude also play a part. Table 1 below shows how the growth classes are derived (source RB209 2017).

Table 1

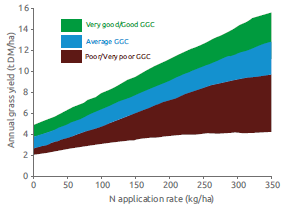

The graph below shows that even at the highest nitrogen application rates the best yields that you can expect from a poor growth potential area will be around half that of the same sward in a very good growth situation (source RB209 2017).

Much of lowland Wales will fall into the ‘Good’ or ‘Very Good’ classification so higher rates of fertiliser will be utilised effectively.

Soils should be tested for pH and nutrient status every 3-4 years. Target pH of 6.5 as nutrient uptake efficiency reduces significantly below pH 6.

More frequent cutting means that slurry can be used “little and often”. Testing organic manures is highly recommended as are accurate applications to avoid over or under supplying certain nutrients as even 34 m3/ha (3000 gallons/acre) of standard slurry will oversupply potassium (K).

Applications of slurry and fertiliser should be made as quickly as possible after each harvest. Trailing shoes or dribble bars are preferred as they will help to minimise leaf contamination and also reduce nitrogen losses to the atmosphere.

RB209 recommends an application of 40kg/Ha of sulphur trioxide (SO3) for each cut on a three cut system- with a multicut system reduce this to 30kg/Ha SO3 over 4 applications.

Timing:

Aim to cut during the first weather window in May and target nitrogen applications accordingly. Subsequent cuts should be targeted at 35 day intervals, but be prepared to go from day 30 if the weather is suitable.

Regrowth rates are key to getting good yields at these short intervals. The photographs below show how much more effective a multicut system is at absorbing sunlight. The later cut sward pictured on the right will take several days before it recovers and puts up green shoots to start photosynthesising and growing again.

Mowing:

For optimum efficiency the capacity of the machinery should be matched so that all operations have the same work rate per hour. Cutting height should be targeted at 6-7 cm to encourage residual photosynthetic rates, which are crucial, especially in new leys. Cutting too low increases potential for drought stress as the plant redirects energy for root growth towards new leaf growth formation in the absence of photosynthesis. There is potential to lose up to 14 days of regrowth time if there is no residual leaf or damage to the apical meristem, this can result in losses of up to 1000kg DM/Ha/cut.

Tedding:

To minimise field losses target dry matter should be at least 35% and achieved within 24 hours of mowing. Tedding should be carried out according to the weather conditions and weight of crop (some crops may need moving twice, others not at all). Where necessary grass should be spread straight after mowing to allow the maximum surface area to be exposed to the elements during the critical two hours whilst the stomata are open.

Chop Length:

Chop length should be varied according to crop dry matter. Wetter crops will require longer material to avoid them turning to a mush. Above 32% DM chop lengths can be reduced to 25mm or even shorter if compact feeding is carried out. Young leafy grass should compact well anyway, but a shorter chop will allow better consolidation. Intakes are generally higher with shorter chop lengths.

Clamping:

Clamping capacity should determine the speed of the harvesting operation. Fill the clamp in long, shallow layers as opposed to using the traditional wedge. If it is possible to clamp multiple cuts in clamps this will lead to more consistent diets during feed out. Put an extra tractor on the pit where possible or use a “Silopactor”.

- Target a density of 250kg DM/m3 of clamp

Additives:

Additives are cost effective, but you need to use the correct ones to get a benefit and they are not a substitute for poor silage making technique. The aim is to get the forage to the correct pH for its dry matter as quickly as possible as any extra time uses valuable nutrients.

As grass is exposed to ultra violet light during the wilting process the “good bacteria” are killed as well as the less desirable ones. To get the fermentation going down the correct pathway towards a stable, lactic dominated silage a dose of the correct type of bacteria can be a big help.

Under most circumstances a lactobacillus plantarum inoculant will drive the correct fermentation and look for a product that supplies 1,000,000 bacteria (cfu)/ gram of grass treated. If feed-out is going to be slow or forage is going to be fed during the summer then bacteria having some acetic acid end products or a preservative such as potassium sorbate can be beneficial in terms of clamp stability.

However, an acetic fermentation uses more energy and the silages do not have such high intake potential. Generally enzymes will be too expensive to put in an additive at sufficient rates to be effective.

Targets:

Cows should be able to consume 15kg + DM/cow/day of high ME silage. This will allow forage: concentrate ratios of 60:40 which will promote excellent rumen health and high yields of milk and solids.

More intensive grassland management will see yields/Ha increase- target 14t DM/Ha and high level clamp management should reduce “shrinkage” losses to 10%.

Costs:

Costs per acre will generally be higher with a multicut system due to the higher levels of inputs and greater harvesting costs. Speaking to your contractor about alternative pricing schedules will be useful (the system works well for them as well as it spreads the work window and lighter crops are much easier on the machinery). Examples of alternative pricing include paying by the hour for the work instead of by the acre or even by the load.

Table 2 below compares a 3 cut with a 5 cut system using representative costs

|

Growing costs £/acre/year |

3 cut |

5 cut |

|

Establishment costs (5 year ley) |

34 |

34 |

|

Fertiliser and spray |

98 |

128 |

|

Slurry spreading |

20 |

28 |

|

Fertiliser spreading/spraying |

16 |

24 |

|

Harvesting |

175 |

275 |

|

Additive/sheets |

26 |

34 |

|

Land rent |

125 |

125 |

|

Total |

494 |

648 |

Table 2

Assumes standard slurry applied up to NVZ maximum of 250kg organic N/Ha

Table 3 follows on from the cost breakdown shown above

Higher dry matter production over the season means that although the cost/tonne of fresh weight is lower in the 3 cut system, when converted to a dry matter basis the multicut system shows a cost benefit just on the amount of material utilised. When the extra energy produced is calculated it shows that the mulitcut system will produce over 50% more MJ/acre which leads to a 14% reduction in cost per MJ.

|

Growing costs £/acre/year |

3 cut |

5 cut |

|

Establishment costs (5 year ley) |

34 |

34 |

|

Fertiliser and spray |

98 |

128 |

|

Slurry spreading |

20 |

28 |

|

Fertiliser spreading/spraying |

16 |

24 |

|

Harvesting |

175 |

275 |

|

Additive/sheets |

26 |

34 |

|

Land rent |

125 |

125 |

|

Total |

494 |

648 |

Table 2

Assumes standard slurry applied up to NVZ maximum of 250kg organic N/Ha

Table 3 follows on from the cost breakdown shown above

Higher dry matter production over the season means that although the cost/tonne of fresh weight is lower in the 3 cut system, when converted to a dry matter basis the multicut system shows a cost benefit just on the amount of material utilised. When the extra energy produced is calculated it shows that the mulitcut system will produce over 50% more MJ/acre which leads to a 14% reduction in cost per MJ.

|

Yield and Dry Matter |

3 Cut |

5 Cut |

|

Tonnes/acre |

15 |

17 |

|

DM |

28 |

35 |

|

Tonnes DM/acre |

4.2 |

5.95 |

|

Clamp losses (%) |

10 |

10 |

|

Amount fed (tonnes DM/acre) |

3.78 |

5.35 |

|

Nutrient values |

|

|

|

Energy ME (MJ/kg DM) |

10.8 |

11.7 |

|

Protein (%in DM) |

14 |

16 |

|

Cost |

|

|

|

Freshweight cost (£/tonne fed) |

36.59 |

42.35 |

|

DM cost (£/tonne fed) |

130.68 |

121.12 |

|

MJ/acre |

40,824 |

62,595 (+53%) |

|

ME cost p/MJ |

1.21 |

1.04 (-14%) |

Table 3

Potential downsides of multicut:

There are many advantages of adopting a multicut system, but there are also some downsides to consider. Table 2 shows the up-front costs are significantly higher than a standard 3 cut system, even though this is a worthwhile investment.

Farmers on the system comment about “silaging all summer” and this involves a lot more sheeting and unsheeting pits, no-ones favourite job, and the logistics of getting contractors on site on extra occasions requires more management time.

In a wet season more passes across the ground for harvesting and slurry spreading will increase the risk of soil compaction which in turn can compromise subsequent yields.

Ensiling immature, leafy grass at lower than ideal dry matters can lead to an increased risk of clamp slippage, particularly when multiple cuts are put in the same pit and layers can slide across each other.

The dry summer of 2018 did result in lighter crops under the multicut system, but that affected all grass management regimes.