Wern Demonstration Site Project Update

Osian Williams and family from Foel near Welshpool, who are a Farming Connect demonstration site, are trialing the use of innovative technology to optimise the environment of their flock of 32,000 laying hens. The project aims to enhance bird health and performance through the use of sensor technology to control air, litter and water quality.

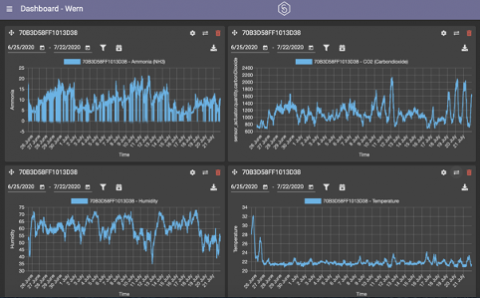

The shed environment is monitored using LoRaWAN technology, which collects data from sensors installed throughout the shed. The results are displayed on a dashboard for Osian to make management decisions. The technology is also connected to the technology that allows for automated adjustments that can improve the flock’s environment.

Figure 1. LoRaWAN sensors installed within the poultry shed.

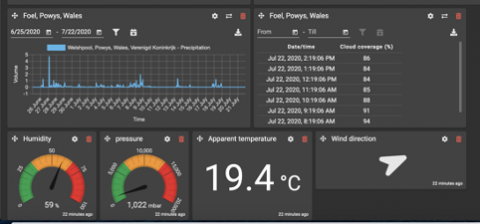

Data collected and monitored inside the building include ammonia, carbon dioxide, temperature and humidity. Additionally, wind direction, temperature, humidity and a range of weather variables are measured and recorded from sensors located outside the building. Conditions outside the shed are monitored as these can all have an effect on ammonia production inside the shed.

Figure 2. Data from the sensors demonstrating ammonia, humidity, carbon dioxide and temperature readings after installation, June 2020.

From the dashboard, we are able to see the changes in the bird’s environment. We are able to make informed decisions to alter the conditions within the sheds and then monitor their effects. For example, the automatic sprayers which spray the Pruex Stabiliser product were repositioned in both sheds recently in the hope to get a better coverage of the product on the manure belts to dry out the manure more effectively. This resulted in drier manure on the belts, which expelled less ammonia.

Figure 3. Data of rainfall, cloud coverage, humidity, pressure, temperature and wind direction outside of the sheds.

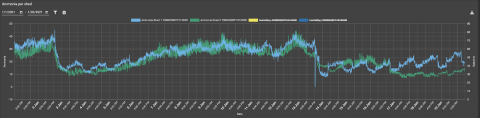

A key focus of the project is to lower and then maintain low ammonia levels, which will benefit bird health and the wider environment. Over the last couple of months, we have been learning about the variations of humidity, temperature and moisture in the winter and finding the optimum ventilation best suited to these variables. We have learnt that the ventilation system of the sheds can greatly affect ammonia levels.

By monitoring and managing the housing using this technology, we identified a drop of 75% in ammonia levels during the warmer months, with levels reducing from 20ppm to 5ppm. Due to the outside humidity being higher during the wetter winter months, the project has recognised that a drop of 75% in ammonia levels is more difficult to achieve. For example, since mid-January, ammonia in shed 2 has been measuring between 8-12ppm and shed 1 fluctuates between 10-25ppm.

Figure 4. Ammonia levels in shed 1 (blue) and shed 2 (green).

Typically, manure in free-range laying units is removed every 3-4 days. Osian is currently removing his unit's manure every 10-13 days; this is due to the success of the automated system being installed, which sprays product onto the manure belts to change the bacteria in the muck/dry it out. As there is less moisture in the muck, it is lighter, allowing Osian to leave it for longer without it causing damage to the bearings of the belts. The muck on the lower two side belts is drier compared to the middle top belt. This could be due to less Pruex Stabiliser reaching the top belts so it is dominant in faecal bacteria.

Figure 5. Manure on belt post treatment (dry)