18 August 2020

Dr Cate Williams: IBERS, Aberystwyth University.

- When excluding feed production, manure produces the most greenhouse gases in the process of pig rearing.

- Housing has a significant impact on nitrous oxide and ammonia emissions, with slatted floors producing 20% less.

- Pig manure is well suited to anaerobic digestion which produces a rich, bio-available fertiliser as well as renewable energy, reducing the environmental impacts of pig farming.

- Using trailing shoe or shallow injection greatly reduces emissions released during land application, particularly when using anaerobic digestate which is highly volatile.

As the most widely consumed meat in the world, pig rearing plays a significant, if not sometimes overlooked, roll in the livestock production industry as much criticism is directed towards ruminants. As farming faces ever more scrutiny in terms of its environmental impacts and greenhouse gas (GHG) emissions, it is important not to forget the contributions that monogastric animals, such as pigs and chickens, make as well as ruminants. Whilst pigs produce 819 million tonnes in CO2 equivalents per year, this is a small figure compared to ruminants which produce 5,024 t. Nevertheless, with an ever-expanding population to feed, we will likely observe an increase in numbers of monogastric animals and therefore an increase in their emissions. A previous article explored the GHGs stemming from digestion (enteric emissions) and feed production and looked at ways in which they might be mitigated. Feeding a low protein (13-14%) diet based on homegrown or domestically-grown protein sources (eliminating or reducing imported soya) alongside specific amino acids provides a promising dietary mitigation strategy. This sort of diet reduces excreted nitrogen (N) which would otherwise be incorporated into ammonia (NH3) and subsequently used to create the potent GHG, nitrous oxide (N2O). Feed production and transport account for a significant amount of GHGs in pig rearing (50-70%) but are often not included in analyses, in which case manure becomes the largest contributor of emissions (up to 89%) making it an attractive target for mitigation measures. This second article will explore how and why GHGs are released from pig manure and how they might be reduced.

Greenhouse gases from manure

Pig manure varies widely in composition depending on the management system and diet but is generally characterised by high nitrogen (N) and carbon (C) levels with variable total solids. Because of the monogastric digestive system, pig’s manure is relatively rich in biodegradable C when compared to a ruminant’s waste, meaning that the potential for CH4 emissions is greater during management. Fermentation in manure is carried out by micro-organisms, some of which are adapted to cope without oxygen (anaerobic) and at warm temperatures. One by one, bacteria colonise particles, converting them into volatile fatty acids (VFAs), CO2 and hydrogen (H2), this process also produces heat and utilises oxygen, creating the ideal environment for other microbes (methanogens) to take these substrates and generate methane (CH4).

There are several routes through which GHGs may be produced in manure:

- Through the conversion of urea into NH3 and CO2.

- Due to the anaerobic fermentation of organic matter into VFAs, CH4 and CO2.

- From aerobic fermentation, usually at the manure surface producing VFAs, CH4 and CO2.

- N2O produced by specialised bacteria during the conversion of NH3.

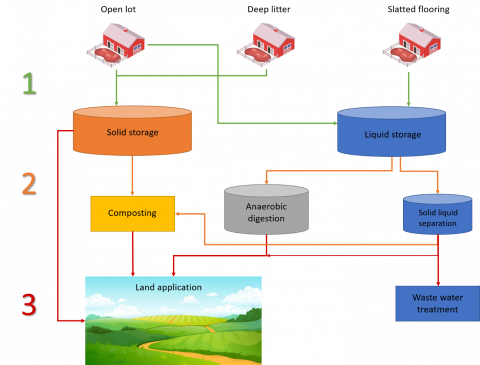

The production of N2O is more common in solid manure than slurry, as bacteria can access oxygen and more solid matter. The level and type of emissions will depend heavily on management methods as there is the opportunity for the release of GHGs at every step, be that during storage or application (Figure 3). After collection, manure is stored either as a liquid (from open units or those with slatted flooring) or as a solid (from deep littered or open lots), solids may then be applied straight to the land, or processed further (Figure 3). The most popular processing methods are anaerobic digestion (AD) or composting, although in some instances liquid and solids are separated before applying the solid fraction to AD (Figure 3).

Figure 3: Schematic representation of storage and treatment options for pig manure (adapted from Dennehy et al., 2017).

Housing

In pig production, the most commonly used housing is a slatted floor with a pit underneath for slurry storage, although there has recently been increased interest in bedded systems due to improved welfare and reduced odour. However, when put to the test, deep littered pigs produced 20% more GHGs than those kept on a slatted floor. Whilst CH4 and CO2 showed less variation, NH3 and N2O emissions almost

doubled in pigs kept on deep litter – indicating that bedding and manure management may be a potential target for mitigation strategies. Whilst rearing pigs on straw improves the brand image for the consumer, it’s not necessarily the most environmentally friendly option. Overall, deep litter provides a more favourable environment for microbes – those producing NH3 need a warm, anaerobic environment and those responsible for N2O production require both aerobic and anaerobic conditions, all of which are provided by deep litter, but not by slurry under slatted flooring. Furthermore, those on deep litter produced 50% more water vapour than those on slatted floors, meaning that increased ventilation would be needed to ensure optimum temperature and humidity is maintained.

There is consistent evidence to suggest that frequent removal of slurry from the pit significantly reduces emissions. This is because the pool of micro-organisms producing methane (methanogenic archaea and bacteria) is removed along with the slurry. In pig houses where slurry was removed and pits cleaned after each fattening period, emissions were 40% lower than in houses where channels were not cleared as frequently.

Storage options

The storage of pig slurry has the potential to release high levels of GHGs as well as causing unpleasant odours. The easiest and most effective method preventing the release of GHGs is covering the pit or tank by sealing hermetically or with a film cover, as in some instances, straw covering has been shown to increase GHG emissions. Studies have found that covering the heap with an airtight material delayed aeration which reduced heat production, degradation of organic matter, and emission of NH3. Emissions of NH3, N2O, and CH4 were reduced by 12%, 99%, and 88%, respectively, when the manure heap was covered with an airtight material compared to no covering at all.

Acidification using lactic or sulphuric acid is also an effective method for reducing emissions. As the pH drops, chemical reactions change and begin to form ammonium instead of ammonia, which does not evaporate. Studies have found that as pH drops, so do NH3 emissions with reductions of 50%, 62% and 77% when pH was reduced to 6.0, 5.8 and 5.5, respectively. A reduction in CH4 production has also been observed, varying from 52% up to 97%. Furthermore, acidification can improve the mineral N equivalence of the slurry by up to 25% enhancing its value as a biofertiliser.

Another method to reduce GHG emissions is to cool the slurry, usually to 15°C or less. Low temperatures slow the production of NH3 and CH4 and the extracted heat may be used to heat livestock housing, however, these systems are complex and expensive and so may not be an option for all.

Treatments

Among the numerous techniques available, AD with the production of biogas offers an opportunity to significantly reduce GHG emissions and the overall environmental impact. This technique harnesses the gases naturally released from manure to produce renewable energy which has the potential to reduce or replace fossil fuels whilst also facilitating nutrient recycling to produce a nutrient-rich biofertiliser. Co-digestion with another substrate such as dairy cow slurry, sewage sludge or food wastes are common to improve buffering capacity and nutrient balance of the digestate. The buffering capacity of pig manure stems from its high levels of NH3, however, it is possible to overload the system with can inhibit the digestion process. Anaerobic digestion also requires C, as such, pig manure should be co-digested with waste that has a high C content to improve the C: N ratio and increase digestive efficiency. Adoption of AD on a Finnish pig farm resulted in an offset of 126 t CO2 equivalents/year and generated 48 MWh of electricity/year, demonstrating the potential benefits of AD. The main issue with AD is the application of digestate in the field, as the highly concentrated and bio-available fertiliser is also volatile (more so than undigested cattle slurry). Studies suggest that shallow injection or direct drilling in the application of digestate significantly reduces emissions arising from field application. Nevertheless, digestate application has been shown to significantly improve above ground biomass generation and overall crop yields (by 5,800 Kg/ha-1) when compared to an untreated control. This is thanks to a large proportion (around 60%) of total N in the digestate being readily available nitrogen and the higher levels of phosphorous in pig digestate when compared to food-based or cattle slurry digestate.

Of particular interest is the fate of antibiotics in pig manure during AD as antibiotic resistance is a pressing issue in pig rearing. Studies suggest that certain antibiotic classes are degraded rapidly during digestion (sulfamethoxazole, erythromycin and trimethoprim) whilst others are more persistent (sulfadiazine and sulfamethizole). As yet, there is no method for the removal or inactivation of antibiotics in manure, as such, the spreading of manure containing antibiotics risks the development of antimicrobial resistance in the environment which may contaminate surrounding land and potentially affect animals. Given the potential benefits of AD, efforts to optimise antibiotic degradation in digestion represent an important area for future research.

The process of composting lends itself to manure with a higher solids content, so is better suited to either the solid fraction after liquid-solid separation or to manure from deep littered systems that contains straw. Studies have found that manure containing only a small amount of straw generates more CH4 and N2O as the manure has a higher density and is less aerated providing ideal conditions for methanogenic microbes. To remedy this situation, the pile might be aerated to reduce the occurrence of anaerobic regions. Studies suggest that a static compost pile (not turned or aerated) generates less NH3 but more N2O, whilst piles turned monthly produced slightly more CH4 but 75% less N2O. The scaling up of compositing still requires further research, as a large-scale compost pile increases the emission rates of N2O and CH4, but smaller piles require a larger area of land to treat the waste. Before composting can become an effective, large-scale mitigation strategy for GHGs stemming from manure, methods need to be optimised to find a technique that is friendly for both the environment and the farmer.

Land application

Spreading pig slurry gives rise to similar issues and emissions as slurry from other animals – CH4 and NH3 which leads to the formation of N2O are of most concern, whilst pig slurry can also be a problem in terms of unpleasant odours. In the EU, regulations are in place stipulating that manure can only be spread on land during spring/summertime, typically when weather is drier thus reducing the risk of runoff. However, thanks to unpredictable rainfall patterns in the UK this can be a challenge and unexpected rainfall can result in runoff, leading to nutrient leaching (N is of particular concern), water pollution, eutrophication and damage to wildlife habitats. As previously discussed, AD of slurry gives rise to a nutrient-rich and valuable fertiliser, but it is also more volatile than undigested slurry and has the potential to release even higher levels of GHGs upon application. As such, it is important to explore alternative spreading methods to broadcasting and band spreading, as well as ensuring applications are well-timed.

Studies suggest that shallow injection or direct drilling in the application of both undigested slurries and digestate from AD significantly reduces emissions arising from field application. One study found that as injection depth increased, CO2 emissions decreased, with a depth of 10 cm producing 23.7 g CO2 whilst injection at 35 cm produced only 2.5 g CO2. Others report a reduction of 40-50% when comparing trailing shoe and shallow injection methods to broadcast spreading, although shallow injection is most effective in reducing emissions upon field application. Other measures to reduce emissions during spreading of digestate include reducing the dry matter content and viscosity of the digestate.

Summary

Manures and slurry from pig production have the potential to emit a significant level of greenhouse gases – CH4, CO2 and N2O – in addition to the problem of unpleasant odours. Nevertheless, utilising pig slurry in AD presents an excellent opportunity to reduce its overall environmental impact. Digestion results in a rich fertiliser containing bio-available nutrients, that can frequently be used to replace bought in fertilisers, AD also allows the production of biogas which may be used to generate renewable energy. The issue with AD is that the digestate produced is volatile and can result in high levels of GHG emissions when applied to the land, as such, it is advisable to use trailing shoe or shallow injection, not only to reduce the potential for emissions but to minimise N losses and ensure optimum uptake by crops. Other methods for reducing the GHG-emitting potential of pig slurry is to use well-built, covered pits and to acidify or cool the slurry which greatly reduces overall N2O release. The type of housing system also has a significant effect on overall GHG emissions, with slatted floors reducing NH3 and N2O production but with deep littered systems improving perceived welfare standards and meeting consumer expectations. When the impact of feed production is excluded, manure accounts for up to 89% of GHGs produced during pig rearing, meaning that this area also has the most potential for mitigation. Many scientific studies support the methods detailed in this article, along with some other alternative strategies, suggesting that there is cause for optimism when it comes to reducing GHG emissions from pig production.