29 June 2021

Dr David Cutress: IBERS, Aberystwyth University.

- Slurry can be both a significant waste consideration as well as a plentiful resource

- Slurry management can be a challenge but improved accuracy through technological innovations could assist with this

- Reducing environmental impacts of slurry management is becoming a focus, with several strategies showing potential towards mitigating these

In 2016 an estimated 83 million tonnes (Mt) of livestock manure was produced annually with 32 Mt of this in the form of undiluted slurry. Based on average slurry densities this is enough to fill the largest lake in the UK, Lough Neagh in Northern Ireland, 62 times over or to fill over 88 million Olympic swimming pools. Correct slurry management and application is vital and as such it is dictated by a specific set of guidelines put forth by Welsh Government which are undergoing changes moving towards 2024. The importance of these controls relates to protecting the environment from ammonia, greenhouse gases (GHGs) and other air, ground and water pollutants that can occur due to handling, spreading and storage of slurry. Chemicals which pass through livestock following treatments can also be present and can impact ecosystems overall. Microbial and viral components of stored slurries also have potential roles in altering ecosystem nutrient cycling. Despite negative aspects of livestock slurries, these can equally act as a relatively sustainable source of nutrients, which if applied correctly can fit well into a system of circular economy and closed-loop nutrient cycling, with clear benefits to utilising organic slurries over synthetic less sustainable equivalents. As farming moves forwards into the realms of technology through the Agriculture 4.0 movement there is a wealth of technology that can directly or indirectly impact slurry storage, handling and application on land. Many of these have proven extremely beneficial whilst others are still in early development but show good promise.

Knowing your nutrients

Nutrient contents of slurries are key to their management as organic fertiliser sources. Where correctly applied slurry can benefit plant productivity massively. Whilst nutrient contents of different organic materials have been researched and are available to interpret (RB209), due to the variable nature of farming these calculations are estimates and can detract from highly accurate application. Management practices such as diet, bedding system and cleaning systems can all affect the waste composition, such as aspects of feed like high cereal concentrates which will increase phosphate more than potash slurry output. Furthermore, total nitrogen (N) content has been shown to vary between 0.1 kg/m3 to 6.5 kg/m3 across UK cattle slurries tested. It is therefore essential that individual farms and growers have their organic materials and slurries tested, for example, via rapid on-farm kits, such as Agros, Quantofix and others, which tend to assess dry matter (DM) and N values utilising hydrometers, electrical conductivity and reflectometers with a range of accuracy. Ideally samples should be sent for accurate laboratory analysis as kit tests can be skewed by abnormally low or high %(DM) values whilst lab tests can determine a full spectrum of qualities including DM, organic matter, potash, sulphur, total nitrogen, phosphates and potassium (K). Even with analysis, it’s important to consider the variability of nutrient content across a single slurry store due to settlement and crusting which can make sample collection an important aspect via correct mixing and agitation.

Whilst slurries contain key nutrients different factors have been demonstrated to play roles in the crop utilisation of N applied and GHGs produced. Factors including time of application, weather surrounding the time of application, method of applications (such as injection vs bandspreader), soil conditions and pre-treatment of slurry can all have impacts, with available N per hectare being up to 3 times higher in best practice scenarios compared to the worst. This is where understanding the nutrient requirements of crops becomes vital in pairing well with nutrient evaluations of slurry. Understanding soil conditions, water flows and even temperature and direct sunlight intensity can help optimise available nutrients and reduce nutrient run-off from fields.

There are also possible pollution risks through the on-farm storage facilities for slurry. Mismanagement, extreme weather and inconsistent maintenance of slurry pits/systems can all have impacts on slurry stores leaking or overflowing and entering the environment. Farmers may even need to address their livestock production levels or seek alternative off-farm applications for their slurry if production outweighs their available application budgets, based on the new regulations. Whilst regulation changes do tighten the application of slurry on agricultural land they also aim to inform farmers of key requirements for storage facilities on the farm to minimise health, environmental and economic risks.

Talking technology

Different technologies can determine nutrient contents and availability within slurries as well as optimising their application and minimising or at the very least assessing their GHG emission related impacts.

Direct slurry management

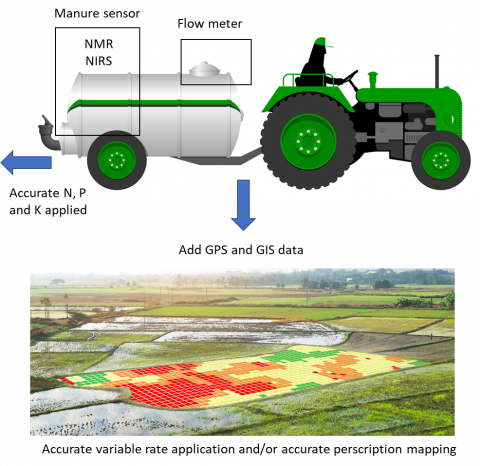

Technologies such as near-infrared spectroscopy (NIRS) are able to perform a quick analysis of animal manures and are showing promise currently for determining carbon and nitrogen fractions and phosphorus (P) content. However, these can suffer from requiring organic material in certain states (eg. finely ground solids as opposed to liquids or vice versa). John Deere for example offer the HarvestLab 3000 which can analyse harvested crops, silage or slurry either during harvest, during spreader filling or application on tankers. Such systems can also be used stand-alone as an on-farm sampling station giving it significant versatility. Mobile or in system low field nuclear magnetic resonance (NMR) systems have also been suggested as a way to monitor N, P, K and indirect organic N content of animal slurries. These systems have undergone optimisation for mobile in-field applications and have relatively lower costs and safety considerations compared to high field equivalent technologies generally used in labs.

Colorimeter technologies (which measure light reflectance and absorbances) can determine N, P and K elements quickly and cost-effectively in soils with variable success. If such technologies can be further refined they could be transferred and calibrated for slurry in the future with potentially lower costs associated. Once nutrient profiles of slurries are understood the correct application on fields can also be bolstered by technologies. Variable-rate technologies (VRTs), whilst often more familiar for systems applying synthetic fertilisers, can also be a powerful tool in slurry spreading. Having a system linked to GPS and pre-mapped nutrient-poor and rich zones can allow automatic control of spreader flow rates.

Considering slurry storage, monitoring technologies can be applied directly as this is a static location where sensors can be situated. Particularly as monitoring of slurry pits manually has been associated with health and safety risk levels on-farm. Whilst on-person gas sensors are already marketed towards farmers for managing slurry, the risks could be reduced further by employing permanent sensors that evaluate conditions before farmers enter a high-risk location. Several wireless communication sensors for various gases are already available on the market. Though research has noted there are potential complications surrounding accuracies of gas sensors with current technologies which need further research and consideration. Other sensors which can assist in managing storage can be fluid level sensors (via liquid pressure or other pressure sensors) with wireless transmission to keep farmers informed as to current storage capacities of not just slurries but also water stores, fuel tanks or groundwater levels. Though slurries, due to combination solid/liquid phases, are notoriously more difficult to assess accurately. Temperature and pH sensors could all add to an inclusive slurry storage management system where, ideally, several sensors would control an automated system that actively switch on and off to agitate or pump slurry. This accurate mixing could minimise gas build-up or settling of nutrients.

Indirect slurry management

Soil sensors and soil mapping techniques can help farmers understand land fertilisation needs, many of these factors have been discussed in a previous article. Other mapping tools for direct analysis of slopes and waterways are also available via satellite or UAV based remote sensing and can all help assess nutrient deployment. Alongside these, smart weather stations integrated into decision making via apps can help to determine far more accurate local weather patterns than broad-scale reports for a region. This can bolster farmer confidence in spreading at the most optimal times to avoid leaching and nutrient losses. Models and simulations have been generated which can determine the best ways and times to apply nutrients to soils as slurries with regards to soil moisture and predictive weather data. However, farmer knowledge of impending ban periods can cause farmers to rush to apply nutrients just before or just after bans reducing productivity and causing damage (as these tend to be suboptimal times of the year to be applying nutrients altogether). Other simulations have also noted impacts from soil compactions in GHG emission levels where slurry spreading by smaller tyre systems led to 20% decreases in N2O emissions. This adds incentives towards the development of autonomous/robotic lower compaction machines or even unmanned aerial vehicle (UAV) targeted applications that can reduce or remove compaction implications entirely.

Total integrated slurry management systems would be the ultimate inclusion of technology and previous propositions combined slurry production controls via ultrasound sensors within slurry pits (to detect slurry level), pressure sensors in slurry spreaders, GPS on tractors and linked recording of spreader position and activity across fields. Systems such as this or similar can automatically draw up electronic reports on slurry management which could be ideal for optimisation and demonstrating adherence to pollution regulations. Positiviely, an EIP Wales project is currently looking at combining many technologies with aims to understand their impacts, optimisation and auditing potentials on commercial farms.

Alternative slurry applications

Chemical amendments such as alum, polyaluminium chloride (PAC), iron chloride, ferric chloride, biochar and a range of food produce waste streams (sugar beet molasses and apple pulp) have been assessed for their potential to mitigate nutrient losses whilst reducing GHGs when added to dairy cattle slurry. Some of these were shown to decrease or increase different GHGs whilst some cause pollution swapping (increasing one pollutant when trying to reduce a different pollutant), suggesting further research is required. Adding beneficial microorganism amendments, in some cases, have noted methane (CH4) and ammonia (NH3) reductions and improved “crust” stabilisation times.

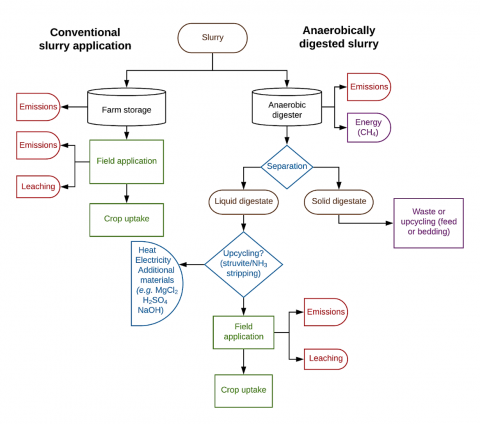

Separation of slurry is also an area that has seen significant research and commercialisation. Separation can be performed in numerous ways including sedimentation, pressurized filtration, screw press and centrifugation. Major proposed benefits of slurry separation are reductions in storage requirements, easier handling and potential for more effective nutrient recycling, whilst some research has indicated the possibility of recycling separate water content back into systems.

Anaerobic digestion is an alternative method of utilising agricultural wastes which involves microorganism mediated material breakdown in conditions lacking oxygen. This breakdown produces available biogases and bioenergy as well as digestate matter with roles in fertilisers and bedding. Anaerobic digestion may reduce the GHG emissions associated with the storage of slurries with up to 43.2% reductions in this stage compared to conventional storage in one study. Smaller scale AD systems seem to be viable in herds of more than 100 cattle with payback periods of 8 – 13 years making it a potential on-farm GHG mitigation strategy as well as a slurry management tool. Both slurry separation and AD have demonstrated benefits compared to traditional storage methods with close to 2-fold decreases in total emissions from separated slurries and more than 2-fold decreases in AD systems. However, recent publications have noted the variability of GHG emissions depending on the separation methodology used with more datasets needed to refine farm-specific recommendations with this technique. Positively, studies have also indicated synergistic benefits when combining AD and slurry separation with regards to both energy production and fertiliser characteristics.

Flow diagram demonstrating the process of conventional slurry storage and application and application to an anaerobic digester. Adapted from Styles et al., (2018).

Whilst both AD and separation techniques are feasible on-farm in some instances it is suggested that higher energy efficiencies are achieved through larger facilities that service multiple farms. This then becomes a logistical consideration when placing AD and separation facilities to best serve multiple farms with minimal transport implications for both incoming supplies of waste and outgoing production of digestate, fertiliser or water.

Summary

Slurry due to its nature can be a complex and variable resource to manage effectively. Huge quantities of manure are produced by current livestock methods and as such improving management is one key area in which agriculture can make beneficial changes towards net zero-emission targets. Slurry is also a vital source of nutrients for recycling back into soil systems, with clear roles in circular ecosystem managment. One of the most essential aspects of slurry management is understanding individual slurry profiles for nutrient levels as this can massively assist in optimised application on fields. Technologies exist commercially towards this process as well as many other direct and indirect aspects of slurry management, which if combined could well improve overall efficiencies, reduce environmental impacts and improve overall sustainability.