Our Farms Project Final Update

Key results

- Expert knowledge on the functionality and practical performance of diverse building designs was a substantial asset, saving time and preventing costly errors in the planning process.

- Housing design inherently involves trade-offs (e.g., financial, space, feed access, comfort). An external perspective was invaluable in optimising the balance of these compromises to prioritise long-term cow health and operational efficiency.

- Tom's proactive guidance led to data-driven decisions that significantly improved cow welfare within the housing, therefore improving herd health and prospectively better farm productivity.

Background

Frances and Deryl Jones are currently reviewing the farm infrastructure, with a view to improve cow health, welfare and productivity, and increasing business efficiency for the future. At the time of this visit, the footings were in place for a new cubicle building for the milking herd, and plans were in discussion for improving dry cow accommodation, handling facilities and investing in a new milking parlour. The Jones’s asked Tom Greenham from Advance Milking to advise on four key areas:

- Optimisation of the new milking cow accommodation.

- Modification of existing dry cow accommodation.

- Design of a new handling system.

- Design of a new milking facility.

Purpose of the work

- Ensure the new milking cow and dry cow accommodation is optimised for cow health, welfare and production.

- Produce a handling system which maximises health, welfare and productivity by facilitating more necessary cow interventions through increasing the speed, ease and safety of management procedures.

- Generate plan options for a new milking facility to improve milking speed whilst also integrating fully with the new buildings and handling system.

What we did

Tom Greenham conducted an online discussion with Deryl and Frances to establish the background to the project together with setting priorities and objectives for the infrastructure improvements.

Following the initial consultation, Tom visited Rhyd Y Gofaint to gain more insight into the herd, the existing infrastructure and the potential of the farm site. This half-day session included an assessment of the range of cow size within the herd, drawing of the existing infrastructure layout and identifying opportunities for change. This included contributions from Deryl and Frances on their proposed ideas.

After the visit, Tom was able to draw up plans for different options of handling system, milking parlour and building layout, mapping out the relationship of these facilities to each other and aiming for efficient utilisation of available space. Plans also included recommendations for the final stages of the milking cow accommodation already in progress.

Outcomes

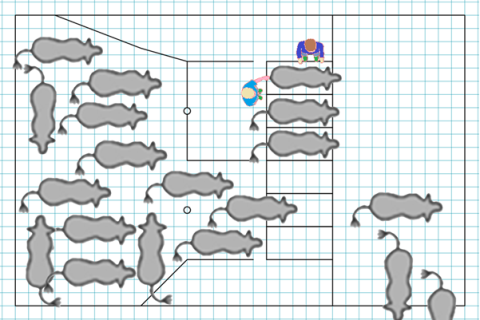

A handling system was designed to achieve the three priorities identified at the visit:

- Capacity for handling twenty animals simultaneously.

- Ready to use immediately within current infrastructure.

- Easy to integrate with future infrastructure (new milking facility, etc).

The facility was designed around rear-loading, front-exit AI stalls, allowing efficient cow flow whilst facilitating safe handling. Swing gates make up most of the partitions allowing flexible use of the system.

Figure 1. Handling system design schematic.

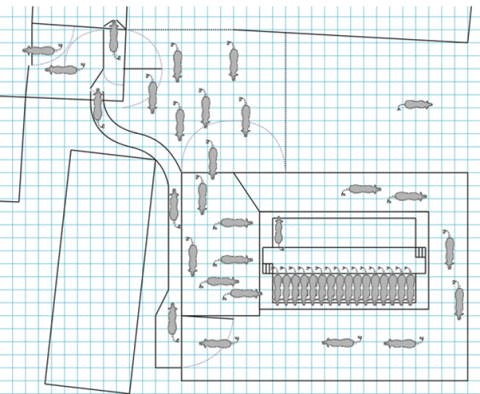

The milking parlour was planned with several options, all utilising a rapid exit milking option to maximise use of the available space. Frances and Deryl had initially thought to install a small rotary parlour to fit the existing building footprint but, on discussion, it was decided that a rotary installation would not be the best fit for Rhyd y Gofaint staffing levels, risking the excellent udder health of this herd. Different layout options have advantages and disadvantages, but all are likely to be a significant improvement to the existing milking facility, achieving the objective of reducing milking duration.

Figure 2. Example of one milking facility option discussed

Deryl and Frances wanted a dry cow housing which could accommodate up to fifty cows, including a transit passage for machinery, without compromising the cow environment. However, the option providing the highest cow health and welfare only accommodates forty-four cows. The option that hits the target number of cubicles for fifty cows will have insufficient feed space and decreased passage area, reducing cow health and productivity. This decision has been left with Deryl and Frances for further consideration.

Recommendations were made on fine-tuning the new milking cow housing. To avoid overstocking the feed face, Advance Milking advised making some of the troughs double sided. It was also recommended to alter plans for the side wall cladding to improve airflow, mitigating poor air quality due to slatted floors over the slurry reception. The slatted surface was also noted as very rough, risking excessive claw horn wear. Advice to mitigate this was included in the report, along with slurry management strategies. With these areas taken into consideration, the new milking cow building should work well for health and production.

How to apply on your farm:

- Remember that building good cow facilities doesn’t take any more time or money than building bad facilities, just more thought!

- Plan ahead, asking lots of questions. Ask experts, ask friends who are happy with their project, and ask friends who aren’t so happy - you will learn something useful from all of them!

- Don’t be afraid of paying for independent, specialised advice - getting input from someone who has worked on similar projects on lots of different farms is an investment that will quickly pay you back.

- Be clear about your objectives and your limitations. You need the project to fit YOUR priorities - so what works for someone else may not work for you.

- Consider how future plans will fit with the existing project -make sure you leave the option for current plans to be integrated with additional infrastructure or management systems.