19 November 2020

Dr Cate Williams: IBERS, Aberystwyth University.

- Whilst the poultry industry is efficient and has a small carbon footprint, issues arise in the production of ammonia, a harmful acidifying agent which impacts the environment and animal and human health.

- Reducing dietary protein and adding essential amino acids is a tested strategy for lowering the nitrogen content of manure, with studies reporting up to 65% reductions.

- Litter treatment using alum or sodium bisulphate is also effective in reducing ammonia emissions, by up to 57%, but work must be carried out to extend these effects past the short term.

- Anaerobic digestion and composting also present an opportunity to process poultry manure in an environmentally friendly way but require further research to make the processes economically viable on a large scale.

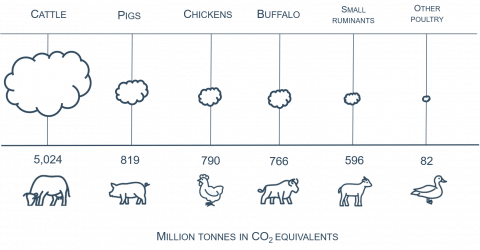

Chicken meat and eggs are among the most common animal-based food sources in the world, with the UK producing 1.94 million tonnes of chicken meat in 2018 and 11.39 million tonnes of eggs in 2019. Despite substantial and consistent increases in production and development of the poultry market year on year, the industry remains the most efficient sub-sector of livestock production in its use of natural resources and the provision of protein to supply growing demands. As discussed in the previous article, chickens are monogastric, meaning that fermentation is minimal and enteric emissions are extremely low, but that is not to say greenhouse gas (GHG) emissions from poultry are negligible (Figure 1). Globally, poultry produces 790 million t/yr of CO2 equivalents, the majority of which arise from manure storage, handling and management, and, whilst often considered elsewhere, the role of feed production cannot be ignored (Figure 1).

Figure 1: Global emissions according to species, expressed in million tonnes of CO2 equivalents, adapted from FAO, 2017.

Many chickens are produced and reared intensively, in indoor units or confined spaces, all of which serve to produce large volumes of concentrated manure. Wales has seen a steady but significant increase in the number of broiler enterprises over the past 10 years and whilst large, industrial systems are less common in the UK when compared to countries such as the USA, their scale and number are on the rise to meet growing demands. Such a rise might be due in part to economic uncertainty as farmers look to diversify their operations, be that into broilers or laying hens. Given the potential in this growing market, it is important to examine the impact of these systems on the environment and aim for sustainable businesses that minimise environmental damage whilst meeting demand.

Emissions from poultry production

Broilers and layers require diets of relatively high protein content to maintain high growth rates and to produce quality eggs, but this also means that unused protein, in the form of nitrogen (N), will be excreted. In most birds, N is excreted in the form of uric acid which is converted by microbes in the faeces to ammonia (NH3). Ammonia is the main pollutant gas arising from poultry production but is not classed as a GHG, despite having significant detrimental impacts on the environment and to animal and human health. As NH3 is an acidifying agent it will contaminate and acidify its surroundings – be that soil or watercourses – which impacts negatively on functionality and has a toxic effect on plant life. Biodiversity is also negatively impacted, as the N supplied by ammonia allows species adapted to a nutrient-rich environment to thrive and out-compete other, more sensitive, smaller or rarer plants. As biodiversity decreases and certain species die out, the effects move up the food chain, impacting insects and amphibians, all of which leads to an unstable ecosystem. In water systems, we see the same effect, as runoff leads to eutrophication – an accumulation of nutrients which leads to algal blooms. As the algae blossoms in excess at the top of the water, this prevents sunlight from reaching other plant and animal life further down, leading to oxygen depletion and a reduction in aquatic biodiversity. Runoff and leaching also represent a loss to the farmer, as N that is not in the soil cannot be taken up and utilised by plants. Ammonia can also be particularly damaging to the respiratory system of humans and animals as when ammonia gas is exposed to moisture, it forms a corrosive solution called ammonium (NH4). This NH4 solution erodes cilia lining the airways, meaning that mucus cannot be swept away which in turn breeds bacteria. Exposure to high levels of NH3 also results in inflammation in the eyes. The vast majority of poultry in the UK are reared indoors on deep litter where NH3 quickly and easily accumulates.

The two key GHGs arising from poultry manure are methane (CH4) and nitrous oxide (N2O), which are produced by microbes in the manure performing methanogenesis and nitrification/denitrification respectively. Whilst nitrogen-converting bacteria require oxygen, methanogenic micro-organisms need a strictly oxygen-free environment, so these processes occur in different areas of the manure – CH4 deep inside of the heap and N2O generation at the top. As the majority of poultry production systems handle manure as a solid, conditions remain mostly aerobic (meaning oxygen is present) and so generates less methane than a slurry or manure under anaerobic conditions. The levels of these gases depend entirely on the nature of the manure as well as the handling and storage method. As well as manure, a great deal of GHGs associated with the poultry industry stem from the fossil fuels used to provide electricity, as particularly in the laying industry, heating is essential. Temperature regulation in the form of cooling may also be necessary, in addition to mechanical ventilation systems and artificial light. However, these contributions tend to be considered elsewhere when it comes to GHG analysis, so they will not be considered within this article.

Nevertheless, poultry produces manure that is rich in N, phosphorous (P) and trace elements that act as a valuable fertiliser in crop production. As with most solid manures, chicken waste can be inconsistent with varying levels of carbon (C) and difficult to spread evenly. As a consequence, spreading restrictions are enforced for such manures with low C:P and N:P ratios. Factors like these can be addressed through processes such as composting, and there is potential for both the improvement of chicken manure as a fertiliser and for the reduction of GHGs and NH3 emissions produced along the way.

Mitigation measures

Managing conditions in the shed

One approach to mitigating GHGs and NH3 in poultry production systems is to alter the composition of the feed – reducing the amount of excess crude protein (CP) given in feed should, in turn, reduce levels of N in waste and lower the risk of its incorporation into N2O or NH3. A common way of doing this is in the form of a low CP diet with targeted amino acids (AAs), a strategy that has been studied and employed in many different types of livestock. Making reductions in the amount of protein supplied, coupled with a more balanced or “ideal” AA profile in the diet can substantially increase the efficacy of overall N retention and contribute to growth rates. There is also potential for this strategy to decrease the C footprint and cost of feed by reducing reliance on soybean and other protein-rich grains. This involves targeting supplementation with essential AAs (those that the chicken cannot produce itself) and any others in short supply. A different ratio of each of these AAs are recommended depending on growth stage:

Essential: Arginine (Arg), isoleucine (Ile), leucine (Leu), lysine (Lys), methionine (Met), phenylalanine (Phe), threonine (Thr), tryptophan (Trp), and valine (Val).

Important: Glycine (Gly), Serine (Ser) and histidine (His).

Studies have used low protein diets ranging from 15 to 20% CP and have supplemented with varying combinations of AA. The effect of low CP diets balanced with AAs is inconsistent, with some suggesting no effect on weight gain although most have found reductions in weight and feed conversion ratio/efficiency (FCR/E) (Table 1). When supplemented with a combination of AAs, often live weight gain and FCR is restored. In laying hens, no differences in the composition or yield of eggs have been reported with low CP diets supplemented with AAs, but reductions in N outputs have been observed (Table 1). Results suggest that reducing dietary CP and balancing this with targeted AAs could be an effective strategy for reducing N excretions of both broilers and laying hens. Further research should seek to establish a recommended list of AAs and their inclusion level in relation to the level of dietary CP provided.

|

Study |

Animals |

CP (%) |

AAs |

Effects |

|

Broiler chicks (growers) |

20 |

Met + Lys |

No differences in production values, but 38% reduction in faecal N compared to a 22% CP diet. |

|

|

22 |

||||

|

Broiler chickens (starter) |

22 |

Gly, Lys + Ser |

19% CP produced a reduction of 24% and 37% in litter N and NH3 emissions respectively, no effect on feathering. |

|

|

20 |

||||

|

19 |

||||

|

Broiler chickens |

1.5 and 3% below recommended |

Lys, Met, Thr, Trp |

Male chicks across all stages showed reduced FCR, but in females this occurred only in the starter phase. Reductions in N excretion of 11.8% in males and 14.6% in females were achieved. |

|

|

Starter |

||||

|

Grower |

||||

|

Finisher |

||||

|

Broilers (growers) |

19 |

Lys, Met, Thr + Trp |

No difference in performance or meat. Faeces N reduced linearly with CP content by 15% and 27% for 18 and 17% CP diets. Foot pad dermatitis was also significantly reduced. |

|

|

18 |

||||

|

17 |

||||

|

Laying hens |

17 |

Lys, Met, Thr, Ile + Cys |

13% CP reduced FCR but 15 and 17% diets had no effect on egg composition or yield. N output per hen/day reduced by 12 and 23% for 15 and 13% CP diets, respectively. |

|

|

15 |

||||

|

13 |

An important influence on ammonia emissions is the characteristics of the litter, for example, temperature, pH, and moisture content. Poultry manure is naturally slightly alkaline (6.5 - 8.0) but decreasing this pH causes a shift from NH3 to NH4 production – a much less volatile compound that is bound into the litter. Various compounds have been trialled that lower the pH of litter, including ferric sulphate, aluminium sulphate (alum) and sodium bisulphate. These compounds may be applied in the shed with birds present. When used in trials, sodium bisulphate has produced reductions in NH3 emissions of 57% which lasted for approximately 11 days. Alum has also been tested with some success, one study found that in addition to reduced NH3 emissions, this litter treatment has the potential to reduce runoff of phosphorous after spreading, improve poultry health and reduce the costs of poultry production. Large scale studies using alum in chick sheds found that treated litter contained more total N and NH4-N which made it a more valuable fertiliser than untreated manure. An ongoing Farming Connect and European Innovation Partnership (EIP) Wales project is currently assessing three different, commercially available litter additives with the aim of reducing N emissions and potentially improving animal welfare and performance.

Moisture content has also been observed to affect NH3 emissions – as moisture content increases, so does NH3 production. The same may be said of temperature, the warmer the shed, the more NH3 is generated. Good management such as maintaining water systems and pipes, ensuring good ventilation, correct humidity and temperatures and preventing condensation build-up can effectively contribute to reducing NH3 emissions.

A Farming Connect demonstration farm based in Welshpool has put some of the above concepts regarding litter treatment and management of shed conditions to the test. The project partnered with Pruex uses a solution of beneficial bacteria sourced from soil to reduce NH3 emissions which has a knock-on effect in improving bird health and productivity. The solution is applied via an automatic sprayer every 2 hours in the shed, bacteria in the solution will out compete nitrifying bacteria in the litter resulting in fewer microbes capable of producing NH3. A similar solution is also applied to water systems to reduce pathogenic biofilm formation which may help to reduce infection in birds. The project has established a system of LoRaWAN-connected sensors to monitor the internal environment (humidity, NH3, CO2, temperature etc.) in addition to outside climatic conditions which serve to inform the frequency of litter treatment. The overall aim of the project is to improve bird health, which is closely connected to reducing NH3 emissions, resulting in more productive animals and potentially improved profitability.

Handling and land application

Another key source of ammonia from poultry manure is during handling and spreading in the field. Whilst chicken manure is a valuable fertiliser that is very rich in N and P, some of this N is in the form of NH3, which quickly and easily volatilises. An excess of P will also pollute the surrounding environment and watercourses, so application rates of poultry manure must be restricted to avoid nutrient leaching. Unlike slurries, chicken litter is drier and classed as farmyard manure, so cannot be applied using methods such as shallow injection or trailing shoe. Instead, good practice should be followed to reduce the risk of nutrient loss, e.g. only spread under optimum conditions, allocate a buffer zone between fields and watercourses and only apply manure in the correct open periods in NVZs. Instead of spreading directly, some may consider alternative routes for poultry manure such as application in anaerobic digestion (AD), composting or the addition of further processing steps.

Composting

The primary aim of composting poultry manure before land application is to alter nutrient ratios, giving a lower but more consistent source of N and P and therefore a more valuable fertiliser. Generally, manure must be co-composted with other substances such as straw, wood chippings, grass or biochar – the latter of which has recently seen a surge in popularity. These additional materials serve as bulking agents, preventing physical compaction of the pile to allow for aeration and, importantly, as a source of C and energy for fermentative microbes. Additional C also helps to balance the C: N ratio of the mixture and reduce N losses during composting.

Biochar is a C-rich material produced through the process of pyrolysis, in itself, biochar is a valuable soil amendment, increasing water holding capacity, pH, soil organic matter (OM) and improving microbial stability. One study used biochar at 3% inclusion with poultry manure and barley straw and found that biochar accelerated OM degradation and increased nitrification, whilst also boosting microbial activity. The biochar also prevented clumping, making for a more stable compost pile. Such rapid OM degradation by biochar may accelerate the entire composting process, authors suggesting production time could be cut by 4 weeks which has the potential to reduce the cost of the process. Other studies agree that the addition of biochar enhances the OM quality of compost using poultry manure, increasing C content and accelerating the overall composting process.

Whilst composted poultry litter is a more valuable fertiliser than fresh poultry litter, it comes with disadvantages – primarily the increased cost and time required for processing. Composting poultry manure would likely be a more attractive option if the end product could be sold at a premium for use in nurseries and gardening.

Alternatively, biochar generated from poultry manure is in itself an effective fertiliser, particularly in crops. This approach avoids the use of raw poultry manure directly on the soil and should bypass some of the environmental issues associated. Biochar incorporation into the soil can have many beneficial effects including enhanced C sequestration, soil fertility, nutrient retention and availability, which translates into increased yields.

Anaerobic digestion

Anaerobic digestion is a sustainable, alternative method for dealing with wastes and manure that is growing in popularity. The ability to co-digest various waste substances and produce biogas and electricity as well as extremely rich and bioavailable fertiliser is certainly attractive. In a similar vein to composting, chicken manure must be co-digested with other substrates to ensure effective digestion by reducing solids, NH3 concentrations (high levels can inhibit digestion altogether), a good balance of nutrients and especially C: N ratio.

One study investigated the co-digestion of poultry manure and sewage sludge, finding that after adding 30% manure, total biogas yield increased by 50%. No ammonia inhibition was observed, but it was reported that AD was insufficient to inactive microbial pathogens – an issue that other studies agree upon. Other trials using only manure from layer hens were able to establish stable AD by supplementing with trace elements, particularly selenium. It was observed that selenium stimulated the process of methanogenesis, resulting in much greater yields of the biogas, methane. The main issue in this trial was the high concentration of ammonia in the resulting digestate – although digestion was not inhibited. Before the widespread use of AD can be applied it seems that further research is required to ascertain optimum co-digestion materials that will produce a less volatile digestate with the potential for further treatment to inactivate pathogens.

Summary

Whilst chickens (both meat and egg-producing animals) are some of the most efficient livestock on the planet, boasting one of the smaller C footprints, issues still stem from their production. Greenhouse gas emissions are technically very low from broiler and laying enterprises, but when other pollutants, particularly NH3, are considered a different image emerges. Ammonia is a volatile acidifying agent, which in the environment can lead to ecosystem instability and a reduction in biodiversity, in the chicken itself, ammonia is damaging to the airways, eyes and skin, eroding the epithelia and causing serious health problems. Ammonia volatilisation and leaching of other nutrients also represent a loss to the farmer, as nutrients are not being taken in by the soil and utilised for growth, instead polluting the surrounding environment. One of the foremost strategies in reducing NH3 in manure is to reduce crude protein in the diet and balance with specific amino acids. Trials have demonstrated success, with reductions in litter N ranging from 11% to 38%, although in some cases there are slight reductions in feed efficiency. Litter treatments have also shown some success, in the short term, reducing NH3 emissions by up to 57% - the next step will entail extending this effect to provide a more economical solution for on-farm use. Reports on the use of poultry manure in AD and composting are mixed as NH3 concentrations are a perennial problem, with the potential to inhibit digestion at high levels and giving rise to an unstable and volatile digestate. However, with some investment in research, these processes could present a feasible avenue for managing poultry manure in an environmentally friendly way.