Dr Natalie Meades: IBERS, Aberystwyth University.

March 2024

Recycled manure solids (RMS) otherwise known as separated manure solids, dairy waste solids or green bedding is an alternative form of bedding for dairy cows.

In the UK and Wales, the use of RMS is restricted to dairy cattle and subject to conditions of use as outlined by the Government. Moreover, farm assurance schemes are likely to have their own criteria regarding its use.

RMS as bedding for dairy cows demonstrates the potential to be a suitable bedding material for dairy cows in terms of providing a bedding low in dust and that promotes cow comfort. However, there are challenges associated with achieving adequate and consistent dry matters and with regards to the potential pathogen load of bedding material and cow health.

Introduction

Bedding is an important part of animal husbandry where it is used to maintain clean, dry hygienic environments as well as providing comfort. However, bedding materials can be costly, subject to availability and exposed to price fluctuations. As such, bedding makes up a considerable proportion of on farm costs. Therefore, it is not surprising that research is being conducted into alternative forms of bedding that can be used on farm. Within dairy systems bedding typically consists of organic (straw, wood shavings or paper-based products) or inorganic (sand, chalk and gypsum) materials. Recycled manure solids (RMS) otherwise known as separated manure solids, dairy waste solids or green bedding is an alternative form of bedding to these conventional materials. This type of bedding makes use of the solid organic matter fraction (undigested fibre) within slurry and can therefore be seen as a sustainable alternative to certain conventional materials.

How are Recycled Manure Solids Produced?

The production of RMS involves the separation of the liquid and solid fractions of slurry. Essentially, slurry is recovered from housing environments and using gravitational or mechanical means the solid and liquid fraction of the manure are separated. Gravitational techniques rely on the natural flow of slurry through weeping walls or via internal separation chambers within slurry pits over prolonged periods of time. Whereas mechanical techniques make use of specialist equipment such as screw press separators, roller presses, vibration, filtration, sieving and decanter centrifuges to separate the solid and liquid fractions and are much faster in comparison. More information on slurry separation technologies can be found in a previous technical article on slurry management. Within the literature, it is apparent that in certain countries manure is often composted or anaerobically digested before use as bedding, however this practice is not permitted within the UK or in Wales.

Recycled Manure Solids as Bedding in the UK

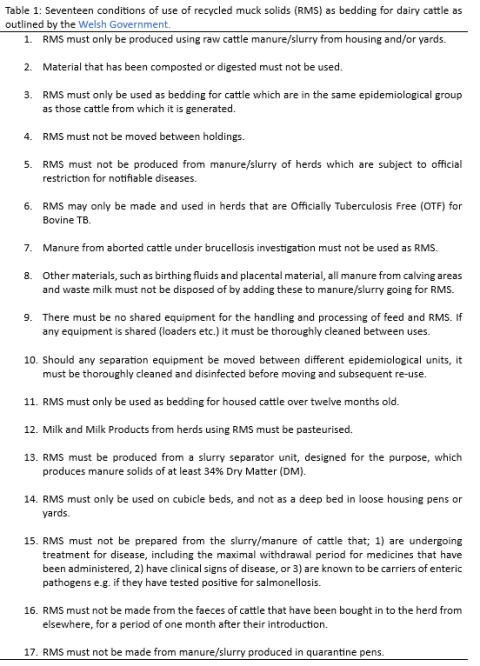

Within the UK and Wales livestock manure and slurry is classified as a category two animal by-product, therefore there are rules and regulations regarding its handling, processing and use. The use of RMS as bedding within the UK is currently restricted to dairy cows and is subject to the conditions outlined in the document “AB143 Conditions of Use in Relation to the Use of Recycled Manure Solids as Bedding for Dairy Cattle”. Moreover, farm assurance schemes such as red tractor have their own regulations regarding use. Likewise, the Welsh Government also have a guidance document “Conditions of use in relation to the use of Recycle Manure Solids (RMS) as bedding for dairy cattle in Wales” which outlines the conditions of use of RMS within dairy systems in Wales. These conditions can be found in Table 1.

Benefits of Producing Recycled Manure Solids on Farm

There are many benefits to producing RMS on farm. Firstly, manure and slurry are readily available and in continuous supply. This means that bedding can be produced on site enabling farms to be more self-sufficient. Moreover, a readily available supply of bedding may result in a more liberal application of bedding to housing environments which could have positive effects on cow comfort. Secondly, RMS is reported to contain less dust in comparison to certain conventional organic and inorganic bedding materials which is of benefit to cow and human respiratory health. Thirdly, separating the solid and liquid fractions of slurry has the benefit of making slurry more manageable by reducing the volume needing to be stored, which can also have positive impacts on the environment. Finally, the use of RMS as bedding has the potential to fit within a circular economy. In such systems, the solid organic matter fraction of slurry can be utilised as bedding for animals and the subsequent liquid fraction can be utilised as a liquid fertilizer owing to the soluble components within it such as nitrogen, potassium, phosphorus and endogenous organic matter. Alternatively, the liquid fraction could have the potential to be purified by green technologies such as phytoremediation, thereby giving the potential for water to be safely discharged into the environment or re-used within systems. More information on phytoremediation can be found by clicking on this technical article.

Recycled Manure Solids and Cow Comfort

The welfare of animals within livestock production systems is essential. It is important that animals can express natural behaviours and are comfortable within the environments that they live in. An important behavioural trait in dairy cows is time spent lying down, where lying down provides an opportunity for cows to rest, sleep and ruminate. A review paper found that dairy cows typically spend on average 10 – 12 hours per day lying down, in which cows typically lie down for approximately 9 – 11 bouts of 60 – 99 minutes. Moreover, lying down allows for the legs and feet to rest, where excessive standing has been identified as a potential risk factor for lameness. Likewise, lying down may also be important for production where a small-scale study involving one dry and one lactating cow observed there to be a 24% greater blood flow to the udder when cows were lying down in comparison to when standing. Therefore, it is important that housing facilities and any bedding provided are supportive of lying behaviour and provide sufficient comfort.

Different bedding materials offer different levels of comfort in comparison to one another. Likewise, cows may have different preferences for different bedding materials over others. RMS can be seen as an appealing bedding material for dairy cow comfort due to its high fibrous composition resulting in a soft, non-abrasive and deformable product. In fact it has been reported that RMS as bedding can have benefits to cow comfort when provided on mats or in deep beds. Moreover, a UK farmer survey reported farmers perceive cows to be comfortable and have increased lying times when bedded on RMS. However, a study discussed that although RMS bedding may be a soft and deformable product this may be a disadvantage with regards to the prevalence of cows developing hock lesions. Where it is thought that the weight of the cows can cause the compression of the bedding resulting in exposure of the rear kerb of stalls to the joints.

The depth of bedding is an important factor to take into consideration. Using leg mounted accelerometers, a study in the UK attempted to predict the daily lying behaviour of lactating dairy cows offered RMS as bedding. The results of the study observed cows to have longer lying bouts by 2.5 minutes on deep RMS bedding in comparison to RMS provided on mats. Moreover, a cross sectional observational study within the upper Mid-West of the United States compared the use of RMS as bedding for lactating dairy cows. The results of the study demonstrated cows bedded on deep RMS in free stalls to have fewer incidences and severity of lameness and hock lesions in comparison to cows bedded on mattresses with RMS. As previously mentioned, one of the main advantages of RMS as bedding is that the substrate (manure and slurry) for producing RMS is readily available on farm, therefore application in sufficient depths is likely to be achievable.

One potential issue with using RMS for bedding is that it has a relatively low dry matter in comparison to other bedding materials. A UK scoping study reported the optimum dry matter for RMS to be 32 – 34 % and that a dry matter lower than this could result in difficulties in handling the product as well as compromising hygiene and quality. Where a low dry matter may provide conditions that are conducive for the growth of potential pathogenic bacteria. As such, the Welsh Government's condition of use of RMS states that the dry matter of bedding needs to be at least 34% to avoid this. In temperate climates such as the UK achieving adequate and consistent dry matters can be particularly challenging in comparison to hot and dry climates in which RMS are more commonly used. It has also been demonstrated that cows have preference for bedding of high dry matters. A study investigated the use of dewatered manure solids (29% dry matter), dehydrated manure solids (90% dry matter) and sawdust (81% dry matter) as bedding for dairy cattle in free choice bedding in stalls. The results of the study demonstrated cows to have preference for bedding with the highest dry matter where cows spent on average 0.5, 5.0 and 4.1 hours per day lying on dewatered manure solids, dehydrated manure solids and sawdust respectively.

Recycled Manure Solids and Animal Health

It is important that the hygiene of lying areas is optimal to encourage lying behaviour and for cow health. It is essential that bedding materials have good absorbency to keep lying areas as dry as possible and to help manage waste. The absorbency potential of bedding materials is therefore an important factor to take into consideration. A study compared the absorbency potential of RMS produced by screw press, composted and oven dried, to chopped wheat straw, sand, pine shavings, chopped newspaper and chopped corn stalks. The results of the study demonstrated the RMS bedding to have the best absorbency in comparison to other test materials.

When bedding becomes contaminated with urine, faeces, leaking milk or from contact with wet or dirty hooves the moisture content within bedding increases. Bedding with a high moisture content can have a negative effect on cow preference for lying down. Moreover, moisture within bedding can compromise bedding hygiene and safety by providing an environment conducive for the growth and proliferation of potential pathogenic microorganisms. Not only that, one of the main concerns regarding the use of RMS as bedding is the potential pathogen load within raw muck and slurry. Likewise muck and slurry can provide substrates for microbial growth and survival. As such, there is concern with regards to the implications of RMS bedding on cow and human health.

A list of pathogens that are likely to have a high load within slurry in the UK can be found documented here. Due to the close contact of the udder with bedding material, a particular area of concern is with regards to the transmission of pathogenic microorganisms that can cause clinical mastitis such as, coliforms (Escherichia spp., Klebsiella spp.), streptococci (Streptococcus uberis, Streptococcus dysgalactiae), Pseudomonas and Trueperella species. As such, research has focussed on this. Within the literature there are conflicts with regards to the implications of RMS bedding on cow health with some studies observing high incidences of bacterial growth and bacterial counts of Streptococcus spp. and Streptococcus-like organisms within bulk tank milk in comparison to other organic bedding materials. In comparison, other studies observed there to be no more of a risk of developing clinical or severe mastitis when bedded down on RMS than on straw. As such it is important that bedding is managed appropriately and kept clean and dry. This is supported by a short communication which observed cows bedded on shallow beds of RMS in the US that were frequently cleaned and replenished to have lower coliform and Klebsiella spp. counts in comparison to deep and infrequently replenished RMS bedding.

Summary

Recycled manure solids (RMS) is an alternative bedding material for dairy cows that is produced following the separation of the solid and liquid fraction of slurry. In the UK and Wales there are regulations regarding its use and it is restricted to dairy production systems. There are many benefits to producing RMS from slurry which include enabling farms to become more self-sufficient, and making slurry more manageable by reducing the requirement for storage. Moreover, RMS has the potential to fit into a circular economy where the organic matter fraction of slurry is recycled and reused. However, considerations are needed as to the costs associated with such technology (capital cost, return on investment, management, servicing and running costs) in comparison to conventional regimes.

Studies have demonstrated RMS to have the potential to act as an alternative bedding material for dairy cattle. Some of the benefits include low dust and cow comfort. However, difficulties may arise in achieving RMS bedding with consistently high enough dry matters. Likewise, there is concern with regards to the safety of use and cow health; this is owing to the potential pathogen load within raw manure and slurry. Moreover, muck and slurry can also provide substrates for microbial growth and survival.