Dr Natalie Meades: IBERS, Aberystwyth University.

April 2024

Manure and slurry can be regarded as both a valuable resource and a waste product.

The valorisation of manure and slurry and its use within circular economies offers an opportunity to reduce waste, improve resource use efficiency and operate production systems in a more sustainable way.

The way in which organic manure and slurry can be managed and utilised in Wales has changed under The Water Resources (Control of Agricultural Pollution) (Wales) Regulations 2021.

Manure and slurry can be valorised in a variety of ways some of which may include, use of recycled manure solids as bedding, a feedstock for renewable energy production and water reclamation.

One of the main by-products of livestock production is the generation of organic waste, namely urine and faeces (excreta). For outdoor reared animals, excreta are deposited on the land and subjected to decomposition by microbiota and weathering by the elements. Whereas for indoor reared animals, faeces and urine are deposited within housing environments and accumulate over time. As such, the excreta from indoor reared animals requires management, which involves regular removal from housing environments and storage. Depending on the consistency and composition of excreta it can either be categorised as manure or slurry. Manure is from here on defined as organic material consisting of faeces, urine and soiled bedding and has a solid like appearance. Slurry is defined as a mixture of manure, faeces and wastewater and has a liquid consistency.

Organic manure and slurry can be viewed as both a waste material and a valuable resource. Within a linear economy, manure and slurry are commonly regarded as waste products. Whereas, in circular economies manure and slurry are regarded as a valuable raw material that can be utilised in a variety of different ways through processes such as reuse, recycling and refurbishment. As such, the valorisation of manure and slurry offers an opportunity to recover components within it and reuse them in other processes in the production cycle. This is beneficial with regards to minimising the volume of waste, improving the efficiency of systems and is a more sustainable option in comparison to waste disposal. More information on the concept of linear and circular economies can be found in a previous technical article.

Manure and Slurry Management in Wales

The way in which organic manure and slurry can be managed and utilised in Wales has changed. As of 1st April 2021 new legislation came into force under The Water Resources (Control of Agricultural Pollution) (Wales) Regulations 2021 with regards to the storage and application of organic manures and slurry on farm. The aim of this new piece of legislation is to put certain rules and regulations in place to reduce agricultural pollution, where manure and slurry can contribute to agricultural pollution following nutrient losses to the environment during the handling, storage and application processes. An example being, the loss of nitrogen and phosphorus to the environment which can contribute to water pollution. Moreover, manure and slurry are a source of ammonia emissions , which can have negative effects on human and livestock health and contribute to poor air quality. In addition, ammonia can also have negative effects on the environment through wet and dry deposition on the land and thereby contribute to the acidification of soils, eutrophication and loss of biodiversity within ecosystems. Manure and slurry are also a source of greenhouse gas emissions which have global warming potential. Methane and carbon dioxide are generated as by-products of the anaerobic fermentation of organic matter within manure and slurry, and nitrous oxide can be generated following the nitrification of ammonium-nitrogen (NH4-N) and the denitrification of nitrate (NO3-).

Since the publication of The Water Resources (Control of Agricultural Pollution) (Wales) Regulations, there has been a gradual three-year transition to its requirements, with set criteria needing to be met by four key dates of 1st April 2021, 1st January 2023, January 2024 – 31st December 2024 and from 1st August 2024. A brief overview of the new regulations and dates for implementation can be found here as presented by the National Farmers Union Cymru. To summarise, changes in legislation result in the requirement for nutrient management planning, sustainable use of fertilizers, fertilizer use in accordance with crop and pasture requirement, the protection of water bodies and new regulations with regards to storage standards.

Composition of Manure and Slurry

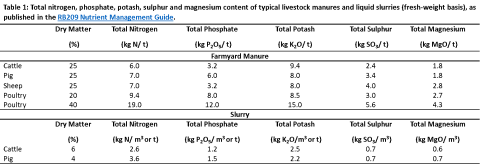

The composition of manure and slurry consists of water, organic matter and nutrients such as nitrogen (N), phosphorus (P), potassium (K(potash)), sulphur (S) and magnesium (Mg) (Table. 1). As such, the recovery of these components through recycling and re-use provides potential pathways for manure and slurry to be valorised and integrated within a circular economy. However, the composition of manure and slurry is variable and dependent on a range of factors such as livestock species, livestock diet, bedding material, and its management (handling, treatment and storage). Therefore, when considering the recovery, recycling and reuse of the components within manure and slurry, it is important to first understand its nutrient composition.

Understanding the nutrient composition of manure and slurry will allow for informed decisions to be made with regards to its management, application and use which will help to promote resource use efficiency. Moreover, understanding the nutrient composition of manure and slurry in conjunction with its use and application has the potential to reduce nutrient losses to the environment which otherwise devalues manure and slurry as a product and has negative effects on air, water and soil quality through pollution pathways. More information on the importance of understanding the nutrient composition of manure and slurry and the various ways in which the nutrients within manure and slurry can be tested for on farm can be found in a previous technical article. The remainder of this technical article will aim to explore the potential pathways in which manure and slurry can be valorised and used within a circular economy.

Organic Fertilizer

The use of manure and slurry as an organic fertilizer is common practice within agriculture, where components within it can be utilised to improve soil health and enhance pasture and crop performance. The organic matter fraction of manure and slurry can improve soil organic matter contents. Moreover, organic matter fraction is a source of carbon which can be utilised as a substrate by soil microbiota for their metabolism, thereby aiding the microbial decomposition of organic matter resulting in the progressive release of plant available nutrients. Manure and slurry are also rich in nutrients such as N, P and K which are important for crop and pasture performance. Nitrogen can be utilised by plants for growth and development and can therefore influence yields and quality. Phosphorus is also important for plant growth and is involved in important processes associated with energy metabolism, the biosynthesis of nucleic acids, the biosynthesis and stability of membranes, photosynthesis, glycolysis, respiration, enzymatic regulation, redox reactions, signalling, carbohydrate metabolism, and nitrogen fixation to a certain extent. Potassium is also important for plant growth and is involved in processes such as osmoregulation, membrane potential regulation, cotransport of sugars, stress adaptation and growth. As such this makes manure and slurry a valuable resource for pasture and crop performance. Moreover, manure and slurry can be seen as an alternative or partial replacement to synthetic fertilizers which are expensive and derived from finite resources.

To get the best out of manure and slurry as an organic fertilizer it is important that it is applied at the correct time when plants are growing, in appropriate weather conditions, at an appropriate application rate and where nutrients are needed. Nutrient management plans can help to achieve this, where plans include information on soil analysis, crop and pasture requirements, nutrient composition of the intended organic fertilizer and where inorganic fertilizers may be needed to top up any deficiencies. If manure and slurry are applied to pasture and crops where there is no benefit to plant performance or when nutrients are provided in excess to plant requirements as part of managing manure and slurry volumes, then manure and slurry are regarded as a waste product. Moreover, excessive use of manure and slurry as a fertilizer can lead to the loss of nutrients to the environment through processes such as erosion, runoff, leaching and volatilization and thereby contribute to the deterioration of air, soil and water quality. As such, it is important to look at opportunities to valorise surplus manure and slurry within agricultural systems. One option may be to sell surplus manure and slurry to neighbouring farms that don’t produce it or set up joint ventures between farms to trade manure or slurry for useful products, for example manure and slurry traded with arable farms for straw.

Although manure and slurry can be seen as a valuable organic fertilizer for crops and pasture there are challenges associated. Slurry contains a high volume of water which can be challenging with regards to handling and storage. Moreover, it can be costly to transport slurry to fields for application, especially when fields are long distances away from slurry stores. However, technologies are available which can help to overcome this, one being separation technology. Separation technology involves the separation of the solid and liquid components of slurry by either gravitational or mechanical means. The resultant solid fraction consists of dry matter that is concentrated in organic matter and phosphorus which can be stored on farm in heaps before application to fields as an organic fertilizer. Moreover, the solid fraction is much easier to handle and transport in comparison to slurry and therefore has the potential to reduce transport costs as well as having the potential to be transported to further destinations in comparison to slurry. The resultant liquid fraction consists of water and soluble components such as organic matter and nutrients N and P. The liquid fraction remains classified as a slurry, however less of a volume needs to be stored on farm in comparison to raw slurry. The liquid fraction also has the potential to be used as an organic fertilizer locally. Furthermore, due to the different nutrient profiles of the solid and liquid fractions of slurry, opportunity arises for a more nutrient targeted fertilizer application approach.

Recycled Manure Solids

The solid fraction of slurry following separation also has the potential to be used as an alternative bedding material. This type of bedding material is known as recycled manure solids, however alternative names are often used for it such as green bedding, dairy waste solids and separated manure solids. In the UK and Wales recycled manure solids are restricted for use to dairy farms and have certain conditions outlining its use.

Recycled manure solids valorise the organic matter fraction of slurry which predominantly consists of indigestible fibre. As such, recycled manure solids can be seen as an appealing bedding material due to its soft, non-abrasive, deformable and low dust characteristics. Studies have demonstrated recycled manure solid bedding to have positive effects on cow comfort. However, there are certain challenges associated with its use. Such challenges may include achieving consistent and adequate dry matter compositions and concerns with regards to the implications on cow health in terms of the pathogen load of slurry. More information on the use of recycled manure solids as bedding can be found in a previous technical article.

Renewable Energy

Manure and slurry can be used as a feedstock for renewable energy production in anaerobic digestion systems. Anaerobic digestion involves the microbial fermentation of organic matter within manure and slurry by hydrolytic, fermentative, acetogenic and methanogenic bacteria. The products of anaerobic digestion are biogas and digestate.

Biogas consists of a mixture of methane, carbon dioxide and trace gases. Carbon dioxide and trace gases can be removed to leave behind biomethane which has similar properties to natural gas. As such, biomethane can be used as a renewable energy source to generate electricity and heat in combined heat and power systems or be used as a fuel source for vehicles. In fact, New Holland have released a model of tractor New Holland T6 Methane Power which has a six cylinder 175 horsepower natural gas engine that can run off biomethane.

The digestate from anaerobic digestion consists of water, nitrogen, phosphorus, humic acids and inorganic matter. Nitrogen is derived from nitrogen bound proteins from feed which is mineralised to ammonium-nitrogen and free ammonia and phosphorus is derived from feed and any inorganic additives and is present as organophosphate. Concentrations are dependent on variables such as livestock type, feeding regimes, manure and slurry management and the anaerobic digestion process itself. As such, the nutrients within digestate can be recovered and recycled as an organic fertilizer for crops and pasture. Moreover, digestate can act as a growth media for certain nutrient tolerant plants and algae, where they can remediate nutrients from the digestate for growth resulting in biomass of a high protein content which has the potential to be fed to livestock and in aquaculture. Furthermore, digestate can be processed again through separation technology to produce solid and liquid fractions. The solid fraction consists of undigested organic matter and nutrients, whereas the liquid fraction consists of soluble components and is more nutrient rich in comparison to the solid fraction. The solid fraction of digestate can be used as an organic amendment. Moreover, the solid fraction has the potential to be utilised as bedding for livestock, although this is currently not permitted in Wales or the UK. Whereas the liquid fraction can be utilised as a mineral-nitrogen fertilizer.

Water Reclamation

Water is an important resource in agricultural systems where it is used by livestock for drinking, used to wash and clean housing areas, machinery, trailers and equipment, used as a diluent and used for irrigation. Slurry contains a high volume of water (>90%) as such there is opportunity to extract this water, purify it and recycle or reuse it within systems or safely discharge it back into the environment with safe discharge licences. Moreover, there is also potential to purify digestate and the liquid fraction of slurry and digestate following the use of separation technology. This process is known as water reclamation.

There are technologies that offer the potential to extract and purify water within slurry. One example being Prosiect Slyri at Coleg Sirgâr, Wales. The aim of this project is to make use of innovative technology to treat raw slurry so that it can be safely discharged back into the environment. The final report for the project details the development of the methodology throughout the project. The resultant methodology includes the separation of the solid and liquid fractions of manure by mechanical means, the processing of the liquid fraction by filtration and centrifugal techniques and treatment in a dissolved air floatation unit. Moreover, the final liquid fraction following processing has the potential to be further purified within reedbeds.

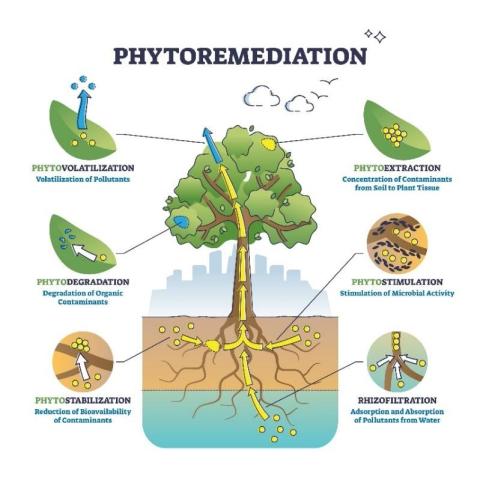

The use of plants to purify wastewaters is a green technology known as phytoremediation. In this instance plants are used to remove nutrients from the liquid fraction of slurry or digestate, thereby cleaning and purifying the water. This technology can be seen as appealing with regards to low cost of implementation and sustainability of practice. The aquatic plant Phytoremediation: The Role of Duckweed in Purifying Agricultural Wastewaters is a good example of this. Duckweed is a fast growing, high yielding aquatic plant that grows well on nutrient rich waters. Duckweed has demonstrated good potential to grow on slurry, digestate and agricultural effluents. The plant acts by extracting the nutrients (N and P) within wastewaters and transforms them into biomass. As such the water fraction left behind is purified and has the potential to be re-used within systems or safely discharged into the environment. Moreover, the subsequent biomass of the Duckweed has the potential to be valorised by acting as a high protein feed for livestock and in aquaculture or as a feedstock for bioenergy production further adding to a circular economy

Summary

Livestock manure and slurry can be seen as a waste resource within linear economy systems. However, in circular economies manure and slurry can be seen as a valuable resource. The composition of manure and slurry consists of water, organic matter and nutrients such nitrogen, phosphorus and potassium which are of benefit to crop and pasture performance. As such, manure and slurry can be seen as a valuable organic fertilizer and can be used to replace/partially replace synthetic fertilizers. However, if manure and slurry are applied to pasture and crops where there is no benefit to plant performance or when nutrients are provided in excess to plant requirements as part of managing manure and slurry volumes, manure and slurry are regarded as waste products. Moreover, excessive use of manure and slurry as a fertilizer can result in the loss of nutrients to the environment through processes such as erosion, runoff, leaching and volatilization and thereby contribute to the deterioration of air, soil and water quality. As such, challenges face farms which generate high volumes of slurry and manure that are in excess to plant requirements. Therefore, it is important to look at the opportunities to valorise surplus manure and slurry within agricultural systems and integrate them into a circular economy. Some of the ways in which this may be achieved include the use of separation technology to create a solid and liquid product for more targeted nutrient applications. The use of the solid fraction of slurry as recycled manure solids as bedding for livestock. The use of manure and slurry as a feedstock for renewable energy. The use of slurry and digestate for water reclamation in processes such as phytoremediation. However, considerations are needed with regards to the costs associated with such processes in terms of capital cost, return on investment, running, servicing and maintenance costs.